Dec . 05, 2024 14:57 Back to list

floating ball check valve

The Floating Ball Check Valve An Essential Component in Fluid Control

In the realm of fluid control systems, one of the crucial components that often goes unnoticed is the check valve. Among the various types of check valves available, the floating ball check valve stands out due to its unique design and functionality. This article will delve into the characteristics, advantages, applications, and maintenance of floating ball check valves.

What is a Floating Ball Check Valve?

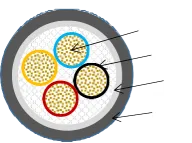

A floating ball check valve is a type of one-way valve that prevents backflow in a piping system. It consists of a spherical ball that floats within the valve body. When fluid flows in the intended direction, the ball is pushed away from its seat, allowing the fluid to pass through. Conversely, if there is a reverse flow, the ball is pushed against the seat, effectively blocking the reverse flow and preventing backpressure.

Key Characteristics

1. Simple Design The simplicity of the floating ball check valve’s design makes it easy to manufacture and install. It typically consists of a valve body, a spherical ball, and a seat. This straightforward construction also allows for easy cleaning and maintenance.

2. Versatile Materials These valves can be constructed from various materials, including brass, stainless steel, and plastic. This versatility enables them to be used in a wide range of applications, from water supply systems to chemical processing.

3. Low Pressure Drop Floating ball check valves are designed to minimize pressure loss, making them suitable for systems that require efficient fluid transport. The absence of complicated mechanisms ensures that there is minimal resistance to flow.

Advantages of Floating Ball Check Valves

1. Reliability One of the primary advantages of floating ball check valves is their reliability in preventing backflow. This feature is critical in applications where fluid contamination or system failure could occur due to reverse flow.

floating ball check valve

2. Low Maintenance With fewer moving parts and a simple operation mechanism, floating ball check valves require less maintenance than other types of valves. Regular inspections and cleaning tasks are often sufficient to keep them functioning correctly.

3. Application Flexibility These valves can be used in a variety of fluid systems, including water, sewage, and even some high-viscosity liquids. Their adaptability to different environments makes them a popular choice in industrial settings.

Applications

Floating ball check valves are utilized in various industries, including

- Water Supply and Wastewater Management They are commonly found in pipelines to ensure unidirectional flow and protect downstream equipment. - Chemical Processing In processes where hazardous chemicals are involved, these valves ensure that backflow does not occur, thereby protecting the integrity of the system. - HVAC Systems Floating ball check valves help in maintaining proper fluid dynamics in heating and cooling systems.

Maintenance and Best Practices

While floating ball check valves require minimal maintenance, regular checks for wear and tear are advisable. Signs of damage or corrosion should be addressed promptly to maintain functionality. Furthermore, ensuring that the valve is installed in the correct orientation and that it matches the fluid properties can significantly enhance its longevity.

Conclusion

The floating ball check valve is a vital component in many fluid control applications, offering reliability, low maintenance, and adaptability across various industries. By understanding their design, advantages, and applications, engineers and technicians can make informed decisions when selecting check valves for their systems. In doing so, they can contribute to enhanced efficiency and safety in fluid transport processes.

Share

-

priming-a-pump-with-a-foot-valve-with-strainerNewsAug.23,2025

-

the-importance-of-a-y-strainer-in-pump-protectionNewsAug.23,2025

-

stainless-steel-ball-check-valve-for-high-purity-applicationsNewsAug.23,2025

-

common-applications-for-wafer-type-butterfly-valvesNewsAug.23,2025

-

seat-options-for-a-12-inch-knife-gate-valveNewsAug.23,2025

-

the-lifespan-of-a-typical-dismantling-jointNewsAug.23,2025