Nov . 05, 2024 09:09 Back to list

flange butterfly valve

The Flange Butterfly Valve A Comprehensive Overview

The flange butterfly valve is a crucial component widely used in various industrial applications to regulate the flow of fluids. Its design incorporates a circular plate or disc that rotates about a central axis, allowing or restricting flow based on the position of the disc. This valve type is particularly favored for its simplicity, effectiveness, and space-saving characteristics.

Design and Construction

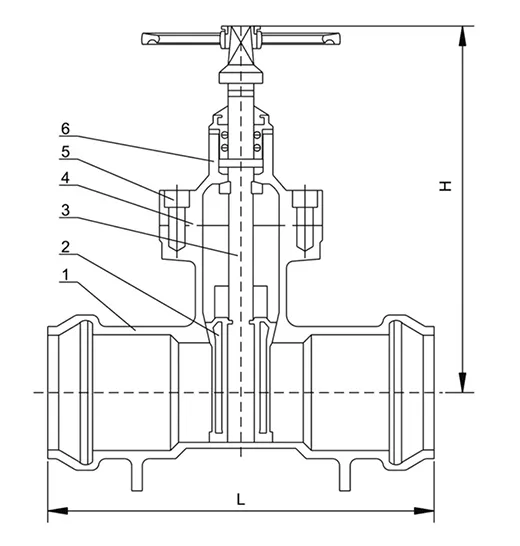

Flange butterfly valves are designed to be installed between two flanges within a pipeline. The primary components include a body, a disc, a stem, and a sealing mechanism. The body is typically made from materials such as cast iron, stainless steel, or plastic, depending on the application requirements. The disc is mounted on a stem, which allows it to pivot either parallel or perpendicular to the flow direction. The sealing mechanism, usually an elastic seat, ensures minimal leakage when the valve is closed.

One of the significant advantages of flange butterfly valves is their compact design. Unlike traditional gate valves, which require more space to operate, a butterfly valve can be fully opened or closed with just a quarter turn of the handle or actuator. This feature makes them ideal for applications where space is limited, such as in HVAC systems, water treatment plants, and chemical processing facilities.

Working Principle

The operation of a flange butterfly valve is straightforward. When the valve is closed, the disc is positioned perpendicular to the flow. When the valve is opened, the disc rotates to a parallel position with the flow, allowing fluid to pass through. This simple mechanism enables rapid operation and can be managed manually or automatically through electric or pneumatic actuators.

Applications

flange butterfly valve

Flange butterfly valves find applications across various industries due to their versatility and efficiency. In water supply and wastewater management, they are used to control flow and pressure. The food and beverage industry relies on these valves for their sanitary design, ensuring product purity during processing. In chemical manufacturing, they are employed to handle corrosive substances, with material selection critical to ensure compatibility with the fluid being transported.

Moreover, flange butterfly valves are also utilized in power plants, where they help regulate steam and cooling water flow. They play a vital role in fire protection systems, where quick action is essential to minimize damage during an emergency.

Advantages

The flange butterfly valve comes with numerous advantages. They are lightweight, making them easy to handle and install. Their design also minimizes pressure drop across the valve, improving system efficiency. Additionally, the ease of operation and maintenance reduces downtime, translating into cost savings for industries.

Moreover, the sealing capability of modern flange butterfly valves allows for excellent shut-off performance, which is crucial in applications where leakage could pose significant risks. The ability to automate the operation further enhances their functionality and integration into modern control systems.

Conclusion

In summary, the flange butterfly valve is an indispensable tool in fluid control across various industries. Its effective design, lightweight construction, and versatility make it a popular choice for engineers and operators alike. As industries continue to evolve, the flange butterfly valve will undoubtedly remain a staple in fluid management and control, proving essential for ensuring safe and efficient operations.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025