Nov . 06, 2024 04:34 Back to list

Ductile Valve Solutions for Enhanced Fluid Control and Durability in Industrial Applications

The Importance of Ductile Valves in Modern Engineering

In the landscape of modern engineering, the significance of valves cannot be overstated. Among various types of valves, ductile valves have emerged as a crucial component in ensuring efficient and reliable fluid control across multiple industries, including water supply, wastewater treatment, oil and gas, and many others. This article will explore the definition, advantages, applications, and maintenance of ductile valves, highlighting their vital role in various engineering applications.

Understanding Ductile Valves

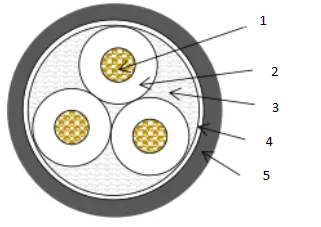

Ductile valves are designed from ductile iron, a material known for its remarkable strength and flexibility. Ductile iron exhibits higher tensile strength and greater resistance to shock and vibration compared to traditional cast iron, making it a safer and more reliable choice for valve manufacturing. These valves often come with a variety of designs, including gate, globe, ball, and butterfly valves, each serving a unique function in fluid control systems.

Advantages of Ductile Valves

1. Increased Strength Ductile valves can withstand high pressures and extreme temperatures, which makes them suitable for demanding applications. The material's strength ensures that the valves maintain integrity even under challenging conditions.

2. Corrosion Resistance Ductile iron is often coated with protective layers, enhancing its resistance to corrosive substances. This property is crucial in environments where valves are exposed to aggressive chemicals, thus prolonging the lifespan of the valve and minimizing maintenance costs.

3. Flexibility and Ductility The flexibility of ductile iron allows for better performance under dynamic conditions. This property is particularly valuable in applications where valves may experience fluctuations in pressure and temperature.

4. Cost-Effectiveness Although the initial investment for ductile valves may be higher than some alternatives, their long-term durability and lower maintenance requirements often render them more cost-effective over their lifespan.

5. Sustainability Ductile iron can be recycled without losing its properties. This characteristic aligns with modern engineering’s push towards sustainability, making ductile valves an environmentally friendly choice.

ductile valve

Applications of Ductile Valves

Ductile valves are widely used in various sectors due to their versatility and reliability. Some key applications include

- Water Supply Systems In municipal water systems, ductile valves play a crucial role in managing water distribution, maintaining pressure, and preventing backflow. Their durability ensures that they can handle the wear and tear associated with continuous use.

- Wastewater Management In wastewater treatment facilities, ductile valves help control the flow of effluents and ensure that pollutants are managed effectively. Their corrosion resistance is a significant advantage in this application.

- Oil and Gas Sector Ductile valves are extensively employed in the oil and gas industry, where they are used to control the flow of crude oil and natural gas. Their ability to withstand extreme pressures and temperatures makes them ideal for such critical applications.

- Industrial Processes In various manufacturing processes, ductile valves are essential for controlling the flow of materials, ensuring production efficiency and safety.

Maintenance and Care

To maximize the longevity and performance of ductile valves, proper maintenance is essential. Regular inspections should be conducted to check for signs of wear, corrosion, or leaks. It is also vital to ensure that valve actuators and seals are functioning correctly. Lubricating moving parts and maintaining clear pathways for fluid flow can help prevent operational issues.

Conclusion

Ductile valves are an indispensable part of modern engineering, offering strength, versatility, and reliability in fluid control applications. Their advanced material properties and diverse functionalities make them suitable for various industries, from water management to oil and gas extraction. By understanding the advantages and applications of ductile valves, engineers and decision-makers can ensure efficient and sustainable operations in their respective fields. Investing in high-quality ductile valves not only enhances performance but also contributes to the overall safety and efficiency of critical systems, making them a vital consideration in contemporary engineering practices.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025