Nov . 23, 2024 21:21 Back to list

ductile iron dismantling joint

Understanding Ductile Iron Dismantling Joints A Comprehensive Overview

Ductile iron dismantling joints are specialized components used primarily in piping systems to allow for easy disassembly and maintenance. These joints are essential in various industries, including water supply, sewage management, and industrial processes. This article will explore the features, benefits, applications, and considerations for using ductile iron dismantling joints.

What are Ductile Iron Dismantling Joints?

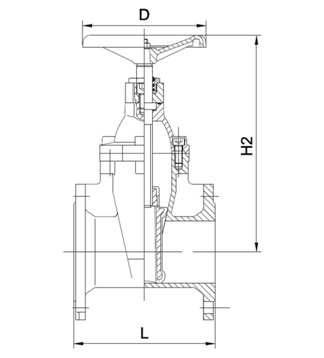

Dismantling joints, sometimes referred to as dismantling flanges, are fittings that facilitate the quick and efficient disassembly of pipeline sections without the need for cutting or extensive modification. Made from ductile iron, these joints provide excellent strength and durability compared to conventional cast iron or steel components. The ductile iron material is advantageous as it offers increased flexibility, resistance to corrosion, and improved tensile strength.

Features of Ductile Iron Dismantling Joints

1. Design Ductile iron dismantling joints typically feature a unique design that incorporates a sliding mechanism. This mechanism allows for axial movement, enabling the sections of the pipe to be easily separated when maintenance is required.

2. Flexibility The inherent flexibility of ductile iron makes dismantling joints capable of accommodating slight misalignments in piping systems. This is particularly beneficial in installations where precision alignment is challenging.

3. Sealing Performance These joints often incorporate advanced sealing technologies to prevent leaks, which is crucial in maintaining the integrity of the piping system.

4. Versatility Ductile iron dismantling joints are manufactured in various sizes and configurations, allowing them to be used in a wide range of applications.

Benefits of Ductile Iron Dismantling Joints

1. Ease of Maintenance One of the primary advantages of using dismantling joints is the ease of access they provide for routine maintenance and repair. Technicians can quickly disassemble the joints, perform necessary work, and reassemble them without specialized tools or excessive downtime.

2. Cost-Effectiveness While the initial investment in ductile iron dismantling joints may be higher than standard fittings, the long-term savings associated with reduced maintenance time and increased system reliability can make them more cost-effective over time.

3. Longevity Ductile iron is known for its durability and resistance to wear and corrosion. Using dismantling joints in systems can lead to longer service life, reducing the frequency of replacements and repairs.

ductile iron dismantling joint

4. Safety The ability to easily disconnect piped systems contributes to safer working conditions. Maintenance staff can operate efficiently with reduced risk of accidents often associated with cumbersome disassembly processes.

Applications of Ductile Iron Dismantling Joints

Ductile iron dismantling joints are utilized across various sectors, including

- Water Distribution In municipal water supply systems, dismantling joints facilitate easy access for repairs and upgrades, ensuring a reliable and safe water supply.

- Wastewater Management In sewage treatment and disposal systems, these joints provide maintenance access to essential components, ensuring that systems function optimally and reducing the likelihood of costly backups.

- Industrial Processes Many industries employ ductile iron dismantling joints in their piping systems for the transportation of materials, fluids, or gases, ensuring that any necessary maintenance can be completed efficiently.

Considerations When Using Ductile Iron Dismantling Joints

While ductile iron dismantling joints offer numerous benefits, there are several important considerations to take into account

1. Material Compatibility Ensure that the ductile iron is compatible with the fluids being transported in the system to avoid corrosion or chemical reactions.

2. Installation Proper installation is crucial for ensuring the performance and longevity of dismantling joints. It is important to follow manufacturer guidelines and ensure that the joints are correctly aligned and secured.

3. Inspection and Maintenance Regular inspection of dismantling joints is advisable to assess their condition and prevent any unexpected failures that could lead to operational disruptions.

Conclusion

Ductile iron dismantling joints are invaluable components in modern piping systems, providing ease of maintenance, reliability, and safety. As industries continue to seek out more efficient and effective solutions for their piping needs, the role of these dismantling joints will only continue to grow. Understanding their features, benefits, and applications is essential for any professional working in plumbing, civil engineering, or industrial maintenance. With the right selection and maintenance, ductile iron dismantling joints can significantly contribute to the operational efficiency and longevity of piping systems.

Share