Nov . 05, 2024 21:47 Back to list

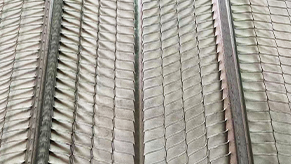

di dismantling joint

The Importance of Dismantling Joints in Industrial Applications

In the realm of industrial engineering, the integrity and reliability of structures and machinery play crucial roles in ensuring smooth operations. One significant component that often comes into play is the dismantling joint. This article explores the importance of dismantling joints, their applications, and considerations for their effective use.

Dismantling joints, as the name suggests, are mechanical components designed to facilitate the easy disassembly of structures or machinery. They are particularly valuable in settings where maintenance, transportation, or modification of components is required. Examples include pipelines, scaffolding, and various manufacturing setups. Their primary function is to provide a secure yet accessible connection between different parts of a system.

1. Key Features of Dismantling Joints

Dismantling joints are characterized by several features that enhance their functionality. These joints typically consist of flanges, bolts, and sealing elements, allowing for secure attachment and detachment. Most importantly, they are designed to withstand the pressures and loads present in industrial environments.

Moreover, they offer flexibility in alignment, which is crucial in applications where pipes or components may need to be adjusted during installation or maintenance. This adjustable feature not only simplifies the assembly and disassembly process but also extends the lifespan of the entire system by preventing undue stress on the connecting parts.

2. Applications in Various Industries

Dismantling joints find applications across a multitude of industries. In the water and wastewater management sector, for instance, dismantling joints are essential for the maintenance and repair of pipelines. They allow for quick access to valves and other components, minimizing downtime and ensuring efficient operations.

In the oil and gas industry, dismantling joints are critical for facilitating transportation and installation of pipelines. Given the hazardous nature of the materials involved, the ability to rapidly disassemble sections of the pipeline can be invaluable during emergencies or maintenance operations.

di dismantling joint

Additionally, these joints are widely used in HVAC systems, allowing for easy access to various components for cleaning and repair. In manufacturing environments, dismantling joints enable efficient assembly lines, making it easier to replace or upgrade machinery as needed without significant disruptions.

3. Considerations for Effective Use

While dismantling joints offer numerous benefits, several considerations must be taken into account to ensure their effective use. One critical aspect is the material selection. Depending on the application, factors such as corrosion resistance, temperature tolerance, and strength must be evaluated. Using the right materials not only ensures the joint's longevity but also maintains system integrity.

Another important factor is the proper design of the joint. Engineers must account for the specific forces and pressures the joint will encounter in its operational environment. A well-designed joint reduces the risk of leaks and structural failures, which could lead to costly downtime or even dangerous situations.

Furthermore, regular maintenance and inspections are paramount. Over time, wear and tear can affect the performance of dismantling joints. Implementing a maintenance schedule helps identify potential issues before they escalate, ensuring system reliability.

4. Conclusion

In conclusion, dismantling joints play a vital role in the modern industrial landscape. Their ability to facilitate easy assembly and disassembly makes them indispensable for maintenance, upgrades, and transportation of various systems. When properly designed and maintained, dismantling joints contribute significantly to operational efficiency and safety. As industries continue to evolve, the importance of such components is likely to grow, highlighting the need for advancements in joint technology and materials.

In the face of increasing demands for efficiency and sustainability, the adoption of dismantling joints will not only improve the functionality of industrial systems but also enhance the overall safety and reliability of operations. Therefore, it is essential for engineers and industry professionals to prioritize the effective implementation of dismantling joints in their projects and operations.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025