Dec . 03, 2024 17:07 Back to list

Gearbox-Equipped Butterfly Valve for Enhanced Performance and Control

Butterfly Valve with Gearbox A Comprehensive Overview

Butterfly valves are essential components in various industrial applications, primarily used for regulating and isolating flow within piping systems. Their uncomplicated design, compact size, and efficient functioning make them a popular choice across a wide array of industries such as water treatment, oil and gas, power generation, and chemical processing. When coupled with a gearbox, the operation of a butterfly valve becomes even more sophisticated, enabling better control and adaptability in different operational conditions.

Understanding Butterfly Valves

A butterfly valve consists of a circular disc or vane that pivots around a central axis within the valve body. By rotating the disc, the valve can vary the flow of fluids passing through it. This straightforward mechanism allows for rapid opening and closing, making butterfly valves particularly suited for services requiring quick responses to flow changes. The simplicity of the design also means fewer moving parts, which translates to potentially lower costs and reduced maintenance needs compared to other valve types.

One of the key advantages of butterfly valves is their ability to handle a large volume of fluid with minimal pressure drop. The disc can either be partially or fully opened, allowing for precise flow regulation. Furthermore, butterfly valves can be manufactured from a wide variety of materials, including stainless steel, carbon steel, and plastic, making them versatile for different environmental conditions and fluid media.

The Role of Gearboxes

A gearbox, or reduction gear, is used to decrease the speed of the actuator mechanism while simultaneously increasing the torque. When integrated with a butterfly valve, a gearbox enhances the valve's operational efficiency, especially in systems that demand significant force to open and close the valve under high pressure conditions. This combination provides several benefits

1. Increased Torque The gearbox multiplies the input torque generated by the actuator, allowing for easy operation of the butterfly valve even in high-pressure applications. This is particularly important in large diameter valves, which often require substantial force to operate.

2. Convenience in Operation Manual operation of larger valves can be cumbersome. The gearbox allows for effortless turning of the butterfly valve by reducing the effort required to achieve the necessary torque.

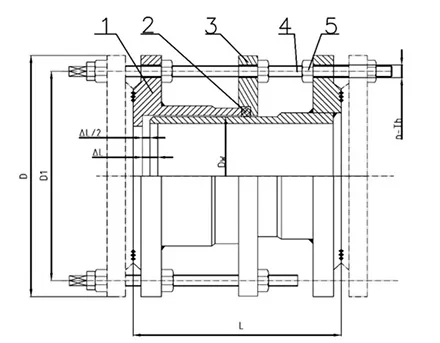

butterfly valve with gear box

3. Enhanced Control By controlling the speed at which the valve opens or closes, a gearbox improves the precision of flow regulation. This responsiveness is crucial in processes where maintaining specific flow rates is vital.

4. Safety Mechanism Gearboxes can include safety features that prevent the valve from being operated accidentally, reducing the risk of damage to the valve or surrounding equipment.

Applications of Butterfly Valves with Gearboxes

1. Water Treatment Facilities Butterfly valves are extensively used in water treatment systems for flow control and isolation. The integration of gearboxes allows operators to manage large flow volumes effectively.

2. Chemical Processing In chemical plants, where harsh chemicals are handled, the robustness of butterfly valves, combined with the operational ease provided by gearboxes, aids in ensuring safe and efficient processing.

3. Power Plants These facilities rely on butterfly valves for regulating steam and water flow. The use of gearboxes in this context allows for the precise management of energy resources, maximizing efficiency and minimizing waste.

4. Oil and Gas Industry With operations often involving high pressures and corrosive materials, the durability and torque-enhancing capabilities of gearboxes combined with butterfly valves ensure reliable and safe handling of such fluids.

Conclusion

The butterfly valve paired with a gearbox represents a sophisticated solution for flow regulation in various industrial applications. The combination of enhanced torque, ease of operation, and precise control makes it an invaluable asset in many sectors. As industries continue to advance technologically, the demand for reliable, efficient valve systems that can adapt to changing operational conditions will likely increase. As such, understanding the functionalities and benefits of butterfly valves with gearboxes is vital for engineers and operators alike to ensure optimal system performance and longevity.

Share