Jan . 13, 2025 16:52 Back to list

Ball Check Valve

Ball check valves have emerged as essential components in various industries, known for their efficient and reliable performance in controlling fluid flow. These unidirectional valves are specifically designed to prevent backflow, ensuring the smooth and consistent operation of piping systems. The expertise around ball check valves has evolved significantly, making them indispensable in modern engineering solutions.

Operational experience with ball check valves showcases their adaptability and low maintenance demands. Industries ranging from oil and gas to water treatment consistently rely on the performance of these valves. Their ability to function without external power further provides an economic and sustainable solution, reducing operational costs and environmental impact. This advantage is particularly pronounced in remote installations where electricity or manual intervention is limited, allowing for autonomous operation solely based on fluid dynamics. Understanding the full range of capabilities ball check valves provide can significantly impact the optimization of fluid control systems. For engineers and professionals tasked with maintaining efficient operations, the choice of a well-designed and reputable ball check valve can determine the performance success of piping networks. By combining a deep understanding of material properties, compliance standards, and operational expertise, professionals can deploy these valves to their maximum potential, offering a robust solution across diverse applications. Ultimately, the growing reliance on ball check valves underscores their crucial role in modern engineering. Their combination of simplicity, reliability, and customizable features make them an ideal solution for preventing fluid backflow across industries. As technology races forward, the need for dependable components like ball check valves will only increase, requiring continuous advancements in design and application strategies to meet the demands of contemporary engineering challenges.

Operational experience with ball check valves showcases their adaptability and low maintenance demands. Industries ranging from oil and gas to water treatment consistently rely on the performance of these valves. Their ability to function without external power further provides an economic and sustainable solution, reducing operational costs and environmental impact. This advantage is particularly pronounced in remote installations where electricity or manual intervention is limited, allowing for autonomous operation solely based on fluid dynamics. Understanding the full range of capabilities ball check valves provide can significantly impact the optimization of fluid control systems. For engineers and professionals tasked with maintaining efficient operations, the choice of a well-designed and reputable ball check valve can determine the performance success of piping networks. By combining a deep understanding of material properties, compliance standards, and operational expertise, professionals can deploy these valves to their maximum potential, offering a robust solution across diverse applications. Ultimately, the growing reliance on ball check valves underscores their crucial role in modern engineering. Their combination of simplicity, reliability, and customizable features make them an ideal solution for preventing fluid backflow across industries. As technology races forward, the need for dependable components like ball check valves will only increase, requiring continuous advancements in design and application strategies to meet the demands of contemporary engineering challenges.

Share

Latest news

-

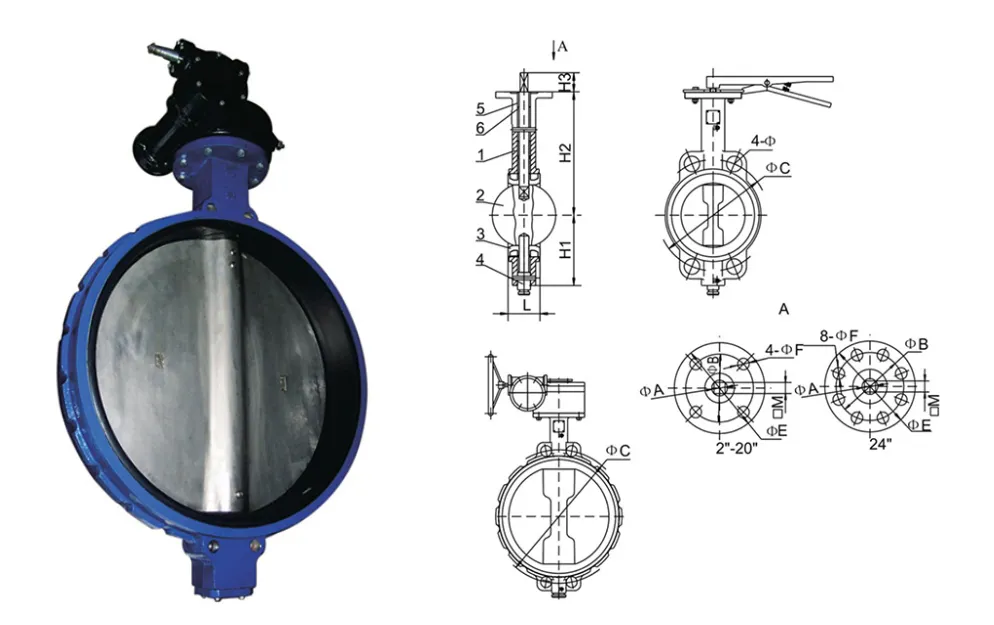

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025