Nov . 07, 2024 18:44 Back to list

Air Release Valve for Efficient Pressure Management and System Safety Solutions

Understanding Air Release Valves Essential Components for Fluid Systems

Air release valves (ARVs) are critical components used in various fluid systems, particularly in water and wastewater management, as well as in industrial applications. Their primary function is to expel air that may accumulate within a pipeline, thereby promoting efficient operation and preventing potential problems associated with air entrapment. In this article, we will explore the significance, working principles, types, and installation considerations of air release valves.

The Importance of Air Release Valves

Air can become trapped in pipelines for several reasons, including changes in elevation, water hammer effects, or variations in flow rates. When air pockets form, they can disrupt the flow of liquid, leading to reduced efficiency and increased operational costs. In critical systems such as water supply networks and sewage treatment plants, the consequences of trapped air can be severe, leading to issues like pressure surges, pipe damage, and even system failures.

Air release valves play a vital role in mitigating these challenges. By allowing air to escape while preventing the loss of fluid, ARVs maintain optimal hydraulic conditions within the system. This proactive approach helps reduce the risk of cavitation, which can erode pipe walls and other components over time, ultimately extending the lifespan of the infrastructure.

How Air Release Valves Work

The design of an air release valve is fairly straightforward yet highly effective. ARVs typically consist of a valve body, a float mechanism, and a vent. Under normal operating conditions, water flows through the pipeline, and any trapped air rises to the top of the valve. As air accumulates, it lifts the float, opening the vent and allowing the air to escape.

Once the air is released, the float drops back down, sealing the vent and preventing the loss of water. This automatic action ensures that the valve operates continuously and does not require manual intervention. Some advanced ARVs also include features like a throttling mechanism or a check valve, providing additional control over airflow and liquid retention.

Types of Air Release Valves

There are several types of air release valves, each designed to cater to specific applications and requirements

1. Simple Air Release Valves Typically used in gravity-fed systems, these valves operate solely based on the presence of air to open and close, functioning effectively for lower flow rates.

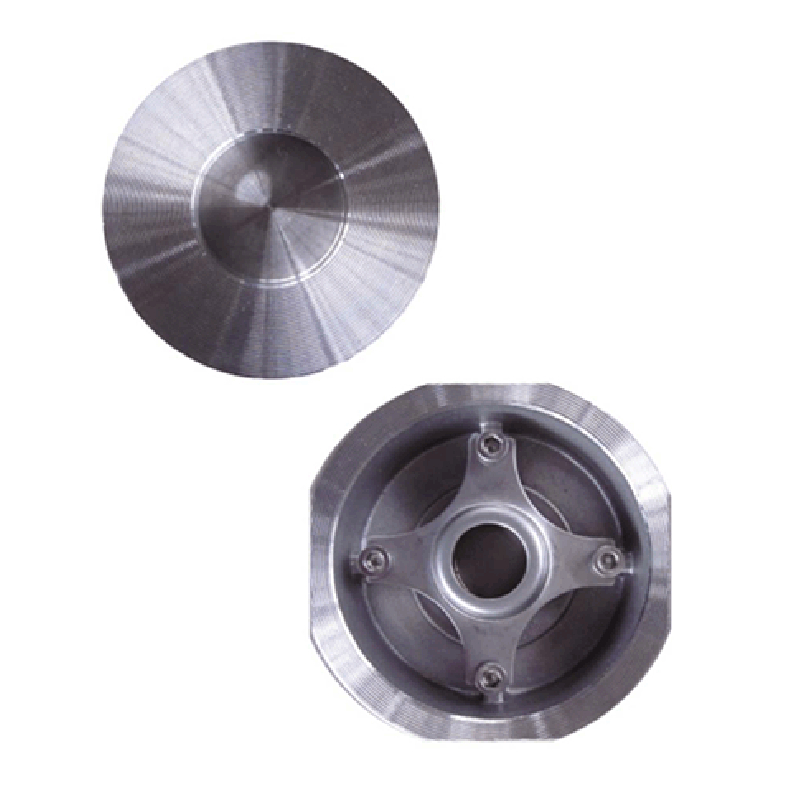

air release valve

2. Combination Air Valves These valves can release air and allow for the intake of air during negative pressure conditions, which is particularly useful in pressurized systems.

3. Automatic Air Release Valves Equipped with sensors and control mechanisms, these valves provide enhanced monitoring and can automatically adjust their operation based on system pressure and flow dynamics.

4. Float Type Valves These are more common in large water distribution networks. The float mechanism is designed to easily respond to changes in air pressure, facilitating rapid air release.

Installation Considerations

When installing air release valves, several factors must be taken into account to ensure optimal functionality

- Location ARVs should be strategically placed at high points in the pipeline where air is likely to accumulate. Additional valves may be necessary at intervals along long stretches of pipeline.

- Sizing It is crucial to select an appropriately sized valve based on the expected flow rates and pressure conditions. A valve that is too small may not sufficiently vent air, while one that is oversized can be costly and unnecessary.

- Maintenance Regular inspection and maintenance are essential for air release valves to ensure they operate correctly. Over time, debris can build up and hinder performance, so periodic cleaning and mechanical checks are advisable.

Conclusion

In summary, air release valves are essential components in fluid systems, actively preventing the adverse effects of trapped air. By maintaining a stable flow of liquids, they not only enhance efficiency but also protect infrastructure from damage. With various types available and clear installation guidelines, understanding and implementing ARVs is vital for anyone involved in maintaining water supply networks or other liquid transport systems. Proper knowledge and care can lead to significant improvements in system performance, reliability, and overall longevity.

Share