Dec . 13, 2024 04:53 Back to list

3 way ball valve

Understanding 3-Way Ball Valves A Comprehensive Overview

In the realm of fluid control, one component plays a crucial role in directing the flow of fluids the 3-way ball valve. This versatile piece of equipment is essential in a wide range of industrial applications, including oil and gas, water treatment, HVAC systems, and chemical processing. The 3-way ball valve stands out for its efficiency and reliability in managing the flow of liquids and gases.

What is a 3-Way Ball Valve?

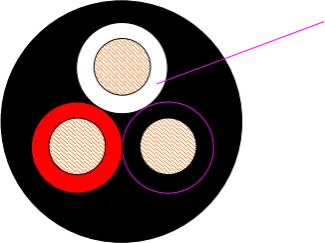

A 3-way ball valve is a type of valve that has three ports, enabling it to regulate flow in multiple directions. Unlike standard 2-way valves, which can either stop or allow flow, 3-way ball valves can divert flow between different paths. The design typically features a spherical ball with a hole in the center, which rotates within the valve body. When the ball's hole aligns with the ports, flow is enabled; when it’s misaligned, flow is blocked.

Types of 3-Way Ball Valves

There are mainly two configurations of 3-way ball valves the L-port and the T-port

.1. L-Port Ball Valves These valves can either mix or divert the flow. They are designed with two inlet ports and one outlet port, allowing for flexible flow control between two different sources. For example, they can blend different liquids or gases in a single outlet line, making them beneficial in mixing applications.

2. T-Port Ball Valves These valves have a T-shaped ball that allows flow from one inlet to multiple outlets, facilitating diversion between different paths. T-port valves are ideal for directing fluid from a single source to two separate destinations, making them suitable for applications that require switching between different operational modes.

3 way ball valve

Advantages of 3-Way Ball Valves

The 3-way ball valve offers several advantages over traditional valve types

- Versatility As mentioned, these valves can control fluid flow in various ways, including mixing and diverting, thus enhancing their application range. - Compact Design 3-way ball valves are typically smaller and lighter than multiple traditional valves required to accomplish similar tasks. This compact design simplifies installation and reduces space requirements in piping systems. - Quick Operation The design of the ball valve allows for rapid opening and closing, minimizing response time, which is crucial in applications where fluid flow needs to be adjusted quickly. - Durability Often made from robust materials like stainless steel or carbon steel, 3-way ball valves are designed to resist corrosion and wear, ensuring longevity and reliability even under harsh conditions.

Applications of 3-Way Ball Valves

The applications of 3-way ball valves are vast. In the oil and gas industry, they are used for diverting flow between pipelines and for controlling fluid mixtures in processing facilities. In the water treatment sector, they play a significant role in managing the distribution of treated water. HVAC systems utilize these valves to balance flow rates in heating and cooling applications. Additionally, in chemical processing, 3-way ball valves assist in mixing different chemical substances safely.

Conclusion

The 3-way ball valve is an indispensable component in fluid control systems, offering efficiency and flexibility that enhance operational capabilities across various industries. Understanding its functions, types, advantages, and applications is essential for engineers and technicians involved in designing and maintaining fluid control systems. As industries continue to evolve, the role of the 3-way ball valve will only grow, underscoring its importance in modern engineering and fluid dynamics. Whether for mixing or diverting flow, the 3-way ball valve remains a reliable choice for professionals seeking optimal performance in their operations.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025