Nov . 05, 2024 22:14 Back to list

Understanding the Functionality and Applications of 12 Inch Knife Gate Valves

Understanding the 12% Knife Gate Valve A Comprehensive Overview

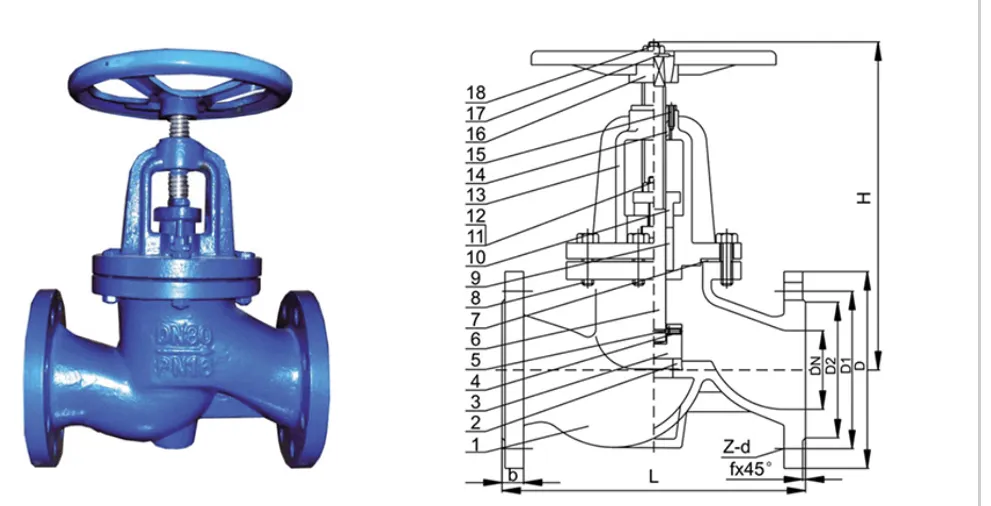

In the realm of industrial fluid control, the knife gate valve is a critical component, known for its efficiency in managing the flow of thick liquids, slurries, or solid-bearing fluids. Among the various specifications and designs, the 12% knife gate valve stands out as a versatile option that meets specific industrial needs. This article will explore the design, functionality, applications, and advantages of the 12% knife gate valve.

Design and Functionality

The term “12% knife gate valve” typically refers to the valve's blade design, incorporating a cutting edge that can efficiently slice through the material passing through it, making it especially effective for slurries and solids. The blade's angle is designed to allow for smooth opening and closing, minimizing turbulence and wear on the valve components.

The gate itself operates in a linear motion, moving up and down to either allow or restrict the flow. Unlike traditional gate valves that operate differently, the knife gate valve is exceptionally designed to handle viscous substances. The valve often includes features like a reinforced body, which adds durability under high-pressure conditions. Typically, the valve is constructed from robust materials such as stainless steel, carbon steel, or specialized polymers, ensuring long-lasting performance even in harsh environments.

Applications

The applications of a 12% knife gate valve are vast and span across multiple industries. They are prominently used in wastewater management, mining operations, pulp and paper production, food processing, and chemical manufacturing. In wastewater treatment plants, for instance, these valves facilitate the handling of sludge and other solid-laden liquids without clogging or causing excessive back pressure.

12 knife gate valve

In the mining sector, they are crucial for controlling the flow of slurries, where water and solids are processed together. The food industry also utilizes these valves for their ability to manage thick, paste-like materials safely and effectively, maintaining hygiene standards while ensuring operational efficiency.

Advantages

The 12% knife gate valve offers several advantages that make it appealing to various industries. First and foremost, its ability to handle solids and slurries effectively without jamming or leaking enhances operational reliability. The design minimizes the risk of clogging, which can be a significant issue with conventional valves.

Moreover, the straightforward linear operation allows for quick actuation, enabling rapid closure or opening as required. This feature is particularly important in processes that demand strict control over fluid flow to optimize efficiency and safety.

The maintenance of knife gate valves is also relatively straightforward, making them cost-effective in the long term. Regular inspections and minimal required downtime due to their robust design contribute to their overall economic viability.

Conclusion

In summary, the 12% knife gate valve represents a crucial innovation in fluid management systems, particularly within sectors dealing with solid-laden fluids. Its unique design, efficient functionality, and range of applications make it an indispensable tool for maintaining effective flow control in a variety of industrial processes. As industries continue to innovate and expand, the demand for reliable mechanisms like the knife gate valve is expected to grow, solidifying its position as a key component in modern engineering and fluid management solutions. Understanding these valves will empower industries to make informed decisions and optimize their operational capabilities.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025