Feb . 15, 2025 01:22 Back to list

industrial check valve

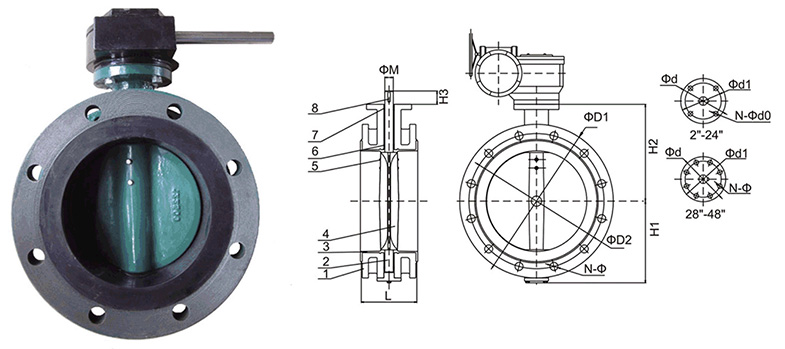

When exploring the intricacies of industrial systems, the fundamental role of check valves cannot be overstressed. As an essential component in piping systems, industrial check valves ensure the unidirectional flow of fluids, safeguarding equipment from potential damages caused by reverse flows. This article aims to delve into the unique aspects of industrial check valves, emphasizing their experience-based advantages, professional selection, authoritative applications, and trust-enhancing features.

Trustworthiness, a cornerstone of any industrial component, is reflected in the robust materials and advanced technologies employed in modern check valve manufacturing. From stainless steel to PVC, manufacturers ensure these valves are engineered to withstand harsh environments and corrosive substances. Computer-aided design (CAD) technologies further enhance their precision and efficiency, resulting in products that not only meet but often exceed industry standards. Moreover, regular maintenance and inspection of check valves bolster their long-term reliability. Professionals in the field advocate for periodic checks to ensure no debris obstructs their operation, as well as the timely replacement of worn-out components. Such practices are testament to the commitment industries have towards maintaining operational excellence. In summary, industrial check valves are a crucial element across various sectors, providing unparalleled reliability and efficiency. Their ability to prevent backflow, degradation, and costly downtime positions them as a critical investment for any industry reliant on fluid dynamics. With the right expertise, informed selection, authoritative utilization, and a commitment to trustworthiness, industries can harness the potential of check valves to maintain seamless operations and protect valuable equipment. By understanding and implementing the best practices associated with check valves, businesses not only enhance their infrastructure but also affirm their commitment to innovation and sustainability. As technology continues to advance, check valves will undoubtedly evolve, promising even greater efficiencies and capabilities tailored to the ever-growing demands of industrial applications.

Trustworthiness, a cornerstone of any industrial component, is reflected in the robust materials and advanced technologies employed in modern check valve manufacturing. From stainless steel to PVC, manufacturers ensure these valves are engineered to withstand harsh environments and corrosive substances. Computer-aided design (CAD) technologies further enhance their precision and efficiency, resulting in products that not only meet but often exceed industry standards. Moreover, regular maintenance and inspection of check valves bolster their long-term reliability. Professionals in the field advocate for periodic checks to ensure no debris obstructs their operation, as well as the timely replacement of worn-out components. Such practices are testament to the commitment industries have towards maintaining operational excellence. In summary, industrial check valves are a crucial element across various sectors, providing unparalleled reliability and efficiency. Their ability to prevent backflow, degradation, and costly downtime positions them as a critical investment for any industry reliant on fluid dynamics. With the right expertise, informed selection, authoritative utilization, and a commitment to trustworthiness, industries can harness the potential of check valves to maintain seamless operations and protect valuable equipment. By understanding and implementing the best practices associated with check valves, businesses not only enhance their infrastructure but also affirm their commitment to innovation and sustainability. As technology continues to advance, check valves will undoubtedly evolve, promising even greater efficiencies and capabilities tailored to the ever-growing demands of industrial applications.

Share

Prev:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025