Ноя . 09, 2024 22:56 Back to list

Understanding the Function and Benefits of Silent Check Valves in Fluid Systems

Understanding Silent Check Valves Importance and Applications

Silent check valves are essential components in various piping systems, designed to prevent backflow while minimizing flow noise. Unlike traditional check valves, silent check valves operate with a unique mechanism that reduces the vibration and slamming sounds commonly associated with fluid flow reversal. This article delves into the functionality, advantages, and diverse applications of silent check valves.

Functionality of Silent Check Valves

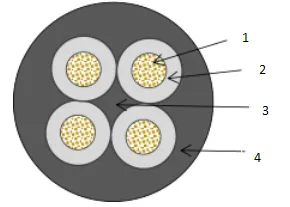

Silent check valves are engineered to allow fluid to flow in one direction while automatically closing to prevent backflow when the flow direction changes. They typically consist of a valve body, a disc or shutter, and a hinge or pivot point. When the fluid flows in the intended direction, the disc is pushed toward the valve seat, allowing for smooth passage. However, if the fluid attempts to reverse direction, the disc quickly seals against the seat, blocking the flow.

One of the most notable features of silent check valves is their ability to close gradually rather than abruptly. This gradual closure reduces the water hammer effect—a phenomenon that occurs due to sudden changes in fluid velocity, often resulting in shock waves that can cause pipe damage and noise. The well-designed mechanism in silent check valves helps to cushion the flow, thereby minimizing the risk of water hammer.

Advantages of Silent Check Valves

1. Noise Reduction The primary benefit of silent check valves is their ability to significantly reduce noise levels in piping systems. This is particularly advantageous in residential and commercial settings where noise pollution can be a concern.

2. Enhanced System Longevity By minimizing water hammer and associated vibrations, silent check valves contribute to the extended lifespan of plumbing systems. This longevity reduces maintenance costs and enhances the overall efficiency of the system.

3. Streamlined Flow Silent check valves provide a more streamlined and unrestricted flow compared to traditional check valves. This can improve the efficiency of pumps and other related equipment, leading to better performance and energy savings.

4. Versatility These valves are available in various materials (such as brass, stainless steel, and PVC) and sizes, making them suitable for diverse applications and environments. This flexibility allows engineers and designers to integrate silent check valves into multiple systems without compromising performance.

silent check valve

5. Ease of Installation Silent check valves are often designed for straightforward installation. Many models incorporate user-friendly features that simplify the process, making it easier for technicians to replace or install new valves.

Applications of Silent Check Valves

Silent check valves find utility in various industries and applications

- Water Supply Systems In municipal water distribution systems, silent check valves prevent backflow, ensuring clean and safe water supply while minimizing noise.

- Fire Protection Systems In fire suppression systems, these valves ensure that water flows only in the intended direction, maintaining system integrity and performance during emergencies.

- HVAC Systems In heating, ventilation, and air conditioning systems, silent check valves help regulate flow, ensuring efficient operation and minimizing noise disturbances.

- Industrial Applications Many manufacturing and processing industries rely on silent check valves to protect equipment from backflow while ensuring operational efficiency.

- Wastewater Treatment In wastewater systems, silent check valves prevent backflow into treatment plants, safeguarding process integrity and enhancing treatment efficiency.

Conclusion

Silent check valves are integral to modern fluid control systems, providing superior backflow prevention while significantly reducing operational noise. With their myriad benefits and broad range of applications, these valves have become a preferred choice for engineers and designers looking to enhance the efficiency and longevity of piping systems. As technology continues to advance, silent check valves will likely evolve, providing even greater reliability and performance in fluid management.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025