Dec . 01, 2024 15:26 Back to list

Dimensions of Butterfly Valves for Different Wafer Types

Understanding Wafer Type Butterfly Valve Dimensions

Butterfly valves are essential components in numerous industrial applications, providing efficient flow control while maintaining a compact design. Among different types of butterfly valves, the wafer type butterfly valve is particularly popular due to its ease of installation and space-saving attributes. Understanding the dimensions and specifications of these valves is crucial for engineers and designers when selecting the right components for their systems. In this article, we will delve into the key dimensions of wafer type butterfly valves, their classifications, and applications.

What is a Wafer Type Butterfly Valve?

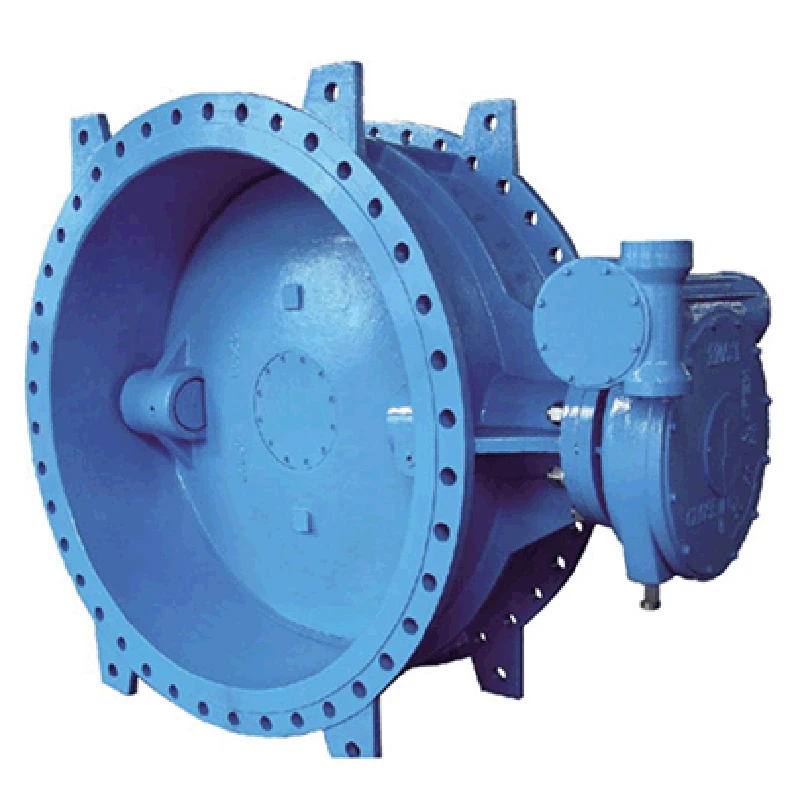

A wafer type butterfly valve is constructed without flanges. Instead, it is installed between two pipe flanges, allowing it to fit directly into the pipeline. This design reduces the need for additional space and material, making it a highly efficient option for many applications. This type of valve primarily features a disc that rotates on a vertical axis, providing either an on (fully open) or off (fully closed) operation.

Key Dimensions of Wafer Type Butterfly Valves

Selecting a wafer type butterfly valve involves understanding a few key dimensions

1. Nominal Pipe Size (NPS) The valve dimensions start with the nominal size (NPS) of the pipeline in which the valve will be installed. Common sizes range from 2 inches to 48 inches, accommodating various flow requirements.

2. Face-to-Face Dimension This is the overall length of the valve from one mounting surface to another. The standard face-to-face dimensions are based on industry standards, such as ANSI or DIN, and can vary depending on the valve size.

3. Body Thickness The thickness of the valve body influences its strength and pressure rating. Thicker valves can withstand higher pressures, making it important to choose a valve that meets the system's pressure requirements.

4. Disc Diameter The effective area of flow through the valve is determined by the diameter of the disc. A larger disc diameter allows more fluid to pass through, which is essential for applications requiring high flow rates.

5. Gearbox or Actuator Size If the valve is equipped with a manual gearbox or an actuator, the dimensions of these components also need to be considered. Actuator size can impact the overall height and installation requirements.

6. Bolt Hole Dimensions When installing a wafer type butterfly valve, the bolt hole dimensions must align precisely with the pipeline flanges. Misalignment can lead to leaks and operational issues.

wafer type butterfly valve dimension

7. Operating Temperature and Pressure Ratings Each valve has specified temperature and pressure ratings that define its operational limits. Ensuring compatibility with these specifications is crucial for safe and effective operation.

Importance of Accurate Dimensions

Using accurate dimensions when selecting wafer type butterfly valves is vital for several reasons

- Compatibility Proper sizing ensures that the valve fits correctly within the existing piping system, preventing installation issues.

- Performance An improperly sized valve can lead to inefficient flow control, increased energy consumption, and potential system failures.

- Safety Valves that are not rated for the appropriate pressure or temperature can pose serious safety hazards, leading to leaks, bursts, or catastrophic failures.

- Cost-Effectiveness Selecting the right valve size can minimize costs associated with over-engineering or frequent replacements due to inappropriate sizing.

Applications of Wafer Type Butterfly Valves

Wafer type butterfly valves are widely utilized across various industries, including

- Water Treatment Used for controlling water flow in treatment plants. - Chemical Processing Ideal for managing corrosive substances due to their robust materials. - HVAC Systems Common in heating, ventilation, and air conditioning systems for flow regulation. - Food and Beverage Made from sanitary materials, they are essential for maintaining hygiene in production lines.

Conclusion

Wafer type butterfly valves offer an efficient solution for flow control across many applications. Understanding the key dimensions and specifications is critical for engineers and purchasing professionals. By carefully considering these factors, one can ensure optimal performance, safety, and reliability in any fluid management system. Choosing the right valve is not just about size; it's about making informed decisions that lead to successful operations.

Share

-

Y Strainers: Protecting Your Pipes with PrecisionNewsAug.27,2025

-

Wafer Type Butterfly Valves: Reliable Flow Control SolutionsNewsAug.27,2025

-

Wafer Type Butterfly Valves: Essential Components for Efficient Flow ControlNewsAug.27,2025

-

Reliable Flow Control with High-Quality Check ValvesNewsAug.27,2025

-

Reliable Flow Control with Gate ValvesNewsAug.27,2025

-

Innovative Check Valves for Reliable Flow ControlNewsAug.27,2025