Nov . 09, 2024 14:38 Back to list

Wafer Type Butterfly Valve for Efficient Flow Control Solutions

The Wafer Butterfly Valve A Comprehensive Overview

In industrial applications, controlling the flow of fluids is vital for ensuring efficient processes. One of the key components that aid in achieving this control is the butterfly valve. Specifically, the wafer butterfly valve has gained significant popularity due to its compact design and versatility in various systems.

What is a Wafer Butterfly Valve?

A wafer butterfly valve is a type of valve that uses a rotating disc to regulate the flow of fluid within a pipeline. Unlike traditional gate or globe valves, which can take up considerable space and require significant force to operate, wafer butterfly valves are designed to be more compact and lightweight. They are inserted between two flanges of a piping system—hence the term “wafer”—and secured with bolts. This design allows them to provide a tight seal while taking up minimal space.

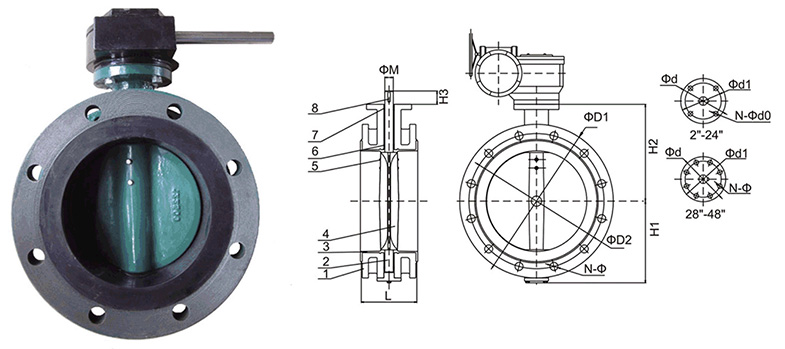

Key Components and Design

The basic structure of a wafer butterfly valve includes

1. Body Typically constructed from materials such as cast iron, stainless steel, or plastic depending on the application's requirements, the valve body encases the internal components. 2. Disc The disc is the part that rotates to open or close the flow. It can be made from similar materials as the body and is designed to create a tight fit against the seat when closed.

4. Actuator This device facilitates the opening and closing of the valve. Actuators can be manual (handwheel) or automated (electric, pneumatic, or hydraulic).

5. Seats The sealing surfaces that prevent leakage when the valve is closed. Seats are often made from elastomeric materials like EPDM or PTFE to ensure a secure seal.

Advantages of Wafer Butterfly Valves

One of the main advantages of wafer butterfly valves is their lightweight and compact nature, which allows for easier installation and maintenance. Here are some additional benefits

wafer butterfly valve

- Efficiency Because of their unique design, wafer butterfly valves have minimal pressure drop across the valve compared to other valve types, making them more efficient in fluid transport.

- Versatility They can handle various types of fluids—liquids, gases, and slurries—making them suitable for numerous applications, including water treatment, HVAC systems, and chemical processing.

- Cost-Effective The simple design reduces manufacturing costs, making wafer butterfly valves a cost-effective solution for flow control in many industries.

- Quick Operation The rotational movement allows for quick opening and closing, which is essential in processes where timely response to flow adjustments is critical.

Applications

Wafer butterfly valves are widely used in many sectors, such as

- Water & Wastewater Management To regulate the flow of water in treatment facilities and distribution systems.

- Food and Beverage Industry Their ability to handle sanitary processes makes them ideal for regulating flow in food production lines.

- Chemical Industry They are capable of handling corrosive fluids and can be designed to meet stringent safety standards.

- Pharmaceutical Industry The valves can be manufactured to meet hygiene requirements, ensuring that the production processes are uncontaminated.

Conclusion

In conclusion, wafer butterfly valves serve a critical role in modern fluid control applications. Their compact design, efficiency, versatility, and cost-effectiveness make them an ideal choice for various industries. As technology advances, the development of these valves continues, promising even more innovative solutions for flow control challenges in the future. Whether you are managing a water treatment plant, a food production facility, or a chemical processing operation, wafer butterfly valves provide a reliable and efficient means of controlling fluid flow. Understanding how these valves work and their benefits can help industries optimize their operations and improve overall productivity.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025