Dec . 22, 2024 07:55 Back to list

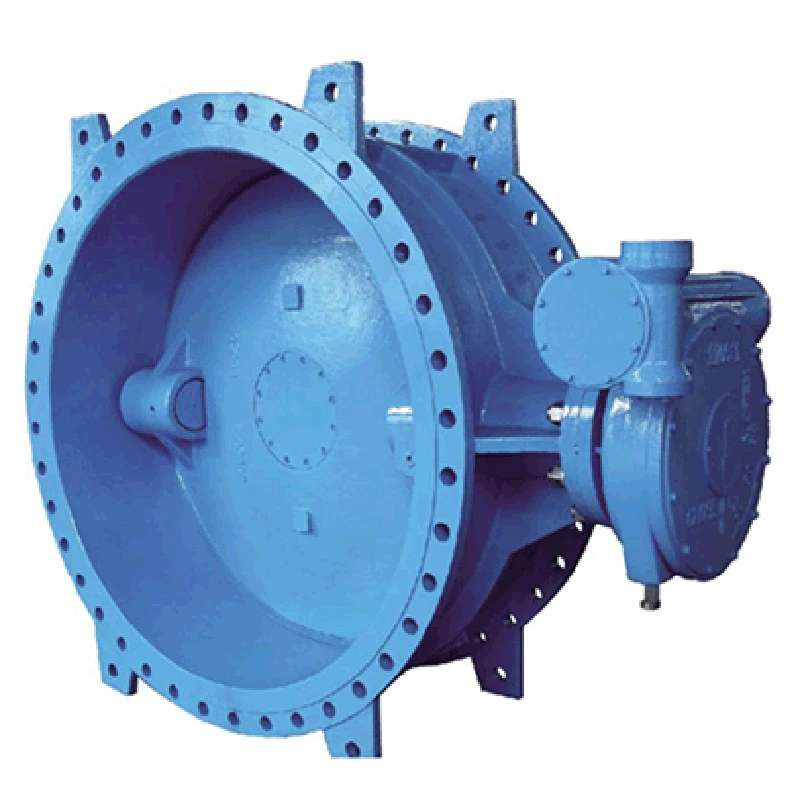

silent wafer check valve

Understanding Silent Wafer Check Valves A Comprehensive Guide

In industrial applications, maintaining the efficiency and safety of fluid transfer systems is paramount. One crucial component that contributes to this efficiency is the check valve, particularly the silent wafer check valve. This type of valve plays a significant role in preventing backflow, ensuring that fluid flows in the desired direction without interruption. In this article, we delve into the mechanics, benefits, and applications of silent wafer check valves.

What is a Silent Wafer Check Valve?

A silent wafer check valve is a device designed to allow fluid to flow in one direction while preventing it from flowing backward. Unlike traditional check valves, silent wafer check valves feature a unique design that minimizes noise generated during operation. They are typically constructed in a thin, flat configuration, making them ideal for situations where space is limited.

The valve consists of two main components the body and the disc. The body is often made from materials such as ductile iron, stainless steel, or PVC, chosen based on the fluid and environmental conditions it will encounter. The disc is designed to move smoothly within the valve body, allowing it to open under forward flow while closing tightly against backflow.

Mechanism of Operation

The operation of a silent wafer check valve is straightforward. When fluid flows through the valve in the designated direction, the pressure pushes the disc upward, allowing the fluid to pass. Once the flow decreases or reverses, the disc is forced back down to its seated position, effectively closing the valve and preventing reverse flow.

The term silent refers to the minimal noise produced during the closure of the valve. This quality is particularly advantageous in residential or commercial settings where noise pollution may be a concern. This feature is achieved through the careful design of the disc and its seating mechanism, which ensures that the closure is gentle and controlled.

Advantages of Silent Wafer Check Valves

1. Reduced Noise One of the primary benefits of silent wafer check valves is their quiet operation. This makes them ideal for installations in sensitive areas where noise levels need to be kept low.

2. Space Efficiency Their compact design allows for easy installation in tight spaces. This feature is beneficial in environments where installation real estate is at a premium.

silent wafer check valve

3. Energy Efficiency By preventing backflow, silent wafer check valves contribute to energy efficiency in fluid systems. This can lead to lower operating costs and increased efficiency in pumping systems.

4. Durability and Reliability Made from robust materials, these valves are designed to withstand harsh conditions, ensuring long-term durability and reliable operation.

5. Minimal Maintenance Silent wafer check valves require little to no maintenance, making them a cost-effective solution over their lifespan.

Applications

Silent wafer check valves are versatile components used across various industries, including

- Water and Wastewater Management In municipal water systems and wastewater treatment plants, these valves play a vital role in preventing backflow that could contaminate clean water supplies.

- HVAC Systems Silent wafer check valves are used in heating, ventilation, and air conditioning systems to ensure efficient fluid dynamics.

- Chemical Processing The ability to handle corrosive fluids makes these valves suitable for use in chemical and pharmaceutical industries.

- Marine Applications They are employed in shipboard systems to prevent unwanted fluid flow in pipes.

Conclusion

Silent wafer check valves are essential components that ensure efficient and reliable fluid flow in various applications. Their unique design not only reduces noise but also offers significant advantages in terms of space, energy efficiency, and maintenance. As industries continue to prioritize efficiency and sustainability, the silent wafer check valve will remain a critical player in fluid management systems. Understanding their operation and applications can help professionals make informed decisions when selecting valves for their specific needs. Whether in industrial, commercial, or residential settings, silent wafer check valves provide the reliability and performance necessary to keep systems running smoothly.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025