Oct . 31, 2024 03:57 Back to list

rsv gate valves

Understanding RSV Gate Valves Functionality and Applications

Gate valves, specifically Rising Stem Gate Valves (RSV), are crucial components in various industrial applications, particularly in the oil, gas, and water sectors. These valves play a significant role in managing the flow of fluids within pipelines, ensuring efficiency and safety in a wide range of operations.

Construction and Design

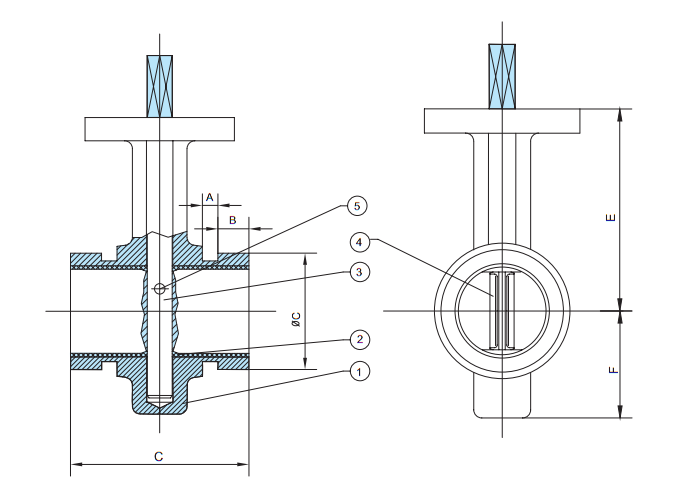

RSV gate valves are designed for on/off service and are characterized by their round body and the way the gate moves vertically to control fluid flow. The structural design consists of a stem that rises or falls when the valve opens or closes. This vertical movement indicates the valve's position, allowing operators to easily monitor its status from a distance. The design not only aids in the quick identification of the valve's state but also prevents potential hazards associated with valve misoperation.

Typically, RSV gate valves are manufactured from materials such as cast iron, stainless steel, or carbon steel, which are selected based on the specific application and the properties of the fluid being transported. The choice of material directly affects the valve's durability, resistance to corrosion, and overall performance.

Operating Mechanism

The operating mechanism of RSV gate valves is straightforward. When the valve is opened, the gate rises completely into the valve body, allowing maximum flow and minimal pressure drop. Conversely, when it is closed, the gate is lowered, blocking the flow entirely. This feature makes RSV valves particularly effective for applications where a complete shut-off is required.

Another advantage of the rising stem design is that it provides a visual indication of whether the valve is open or closed. The position of the stem, which extends above the valve, serves as a useful reference point for operators, enhancing operational safety.

rsv gate valves

Applications

RSV gate valves are widely utilized in numerous sectors. In the oil and gas industry, they are employed in pipelines to regulate the flow of crude oil and natural gas. Water treatment facilities also rely on these valves to control the distribution of potable water. Additionally, they are commonly used in fire protection systems and irrigation projects, highlighting their versatility across different environments.

Advantages and Limitations

One of the primary advantages of RSV gate valves is their ability to provide a full flow area, which means minimal turbulence and friction loss when the valve is open. This characteristic enhances the overall efficiency of fluid transfer systems.

However, there are limitations to consider. RSV gate valves are not well-suited for throttling applications, as they perform best when fully open or fully closed. Furthermore, the rising stem mechanism requires additional space for operation, which may not be feasible in all installations.

Conclusion

In summary, RSV gate valves are essential components for managing fluid flow in various industries. Their simple yet effective design offers many advantages, including ease of operation and visual position confirmation. While they are not suitable for all applications, their robust performance in on/off control makes them a popular choice for engineers and operators looking to maintain efficiency and safety in their systems. As industrial demands continue to evolve, the role of RSV gate valves will remain significant in ensuring reliable fluid management.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025