Nov . 16, 2024 23:25 Back to list

reflex rubber expansion joint

The Advantages and Applications of Reflex Rubber Expansion Joints

Reflex rubber expansion joints are critical components in various piping and ducting systems. Their primary function is to accommodate movement, absorb vibrations, and compensate for thermal expansion or contraction in fluid and gas transport systems. These joints are designed to promote flexibility, reduce stress on connected piping, and prolong the lifespan of the infrastructure. In this article, we will explore the advantages, construction, and applications of reflex rubber expansion joints.

Understanding Reflex Rubber Expansion Joints

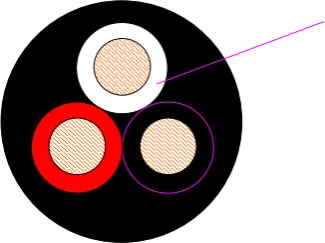

These expansion joints are typically made from high-quality rubber materials, including natural rubber, neoprene, EPDM, and silicone. The construction usually involves layers of rubber bonded together with fabric or metallic reinforcements, ensuring durability and flexibility. The unique design of the reflex rubber expansion joints allows them to flex and adapt to changes in temperature and pressure within the system, effectively absorbing line movement due to thermal expansion, mechanical vibrations, or seismic activity.

Key Advantages

1. Flexibility and Movement Accommodation One of the primary benefits of reflex rubber expansion joints is their ability to accommodate misalignments and vibrations. In any piping system, pipes may experience displacement due to thermal expansion or ground shifts. The flexible design of these joints allows them to absorb these movements, which helps to prevent damage to the piping systems.

2. Vibration Damping Reflex rubber materials are excellent at damping vibrations. Pumps and compressors can transmit vibrations throughout the piping system, leading to wear and tear. By incorporating reflex rubber expansion joints, the transmission of vibrations is significantly reduced, contributing to a quieter operation and decreased maintenance costs.

3. Ease of Installation Reflex rubber expansion joints are relatively lightweight compared to their metallic counterparts. This lightweight nature makes them easier to handle and install. Additionally, they can be cut to size to fit various applications, further enhancing their versatility.

4. Corrosion Resistance Rubber materials are not susceptible to corrosion in the same way that metals are. This characteristic makes reflex rubber expansion joints an ideal choice for environments where corrosive substances are present, such as in chemical processing plants or wastewater treatment facilities.

5. Cost-Effectiveness The overall cost of operating and maintaining systems equipped with reflex rubber expansion joints tends to be lower due to their durability and resilience. Although they may require replacement periodically, their initial and ongoing costs are generally lower than those of rigid or metallic expansion joints.

reflex rubber expansion joint

Applications Across Various Industries

Reflex rubber expansion joints find application in a wide range of industries due to their versatility. Some notable applications include

- HVAC Systems In heating, ventilation, and air conditioning systems, these joints are essential for ensuring proper airflow and compensating for thermal expansions.

- Chemical Processing The chemical industry often uses reflex rubber expansion joints due to their resistance to various chemicals and high flexibility, which helps manage the movement of pipes under varying conditions.

- Water and Wastewater Treatment In municipal and industrial water treatment facilities, these joints reduce stress in pipelines, preventing leaks and prolonging the system's lifespan.

- Power Generation In power plants, expansion joints are used to handle the thermal fluctuations and vibrations caused by turbines and generators.

- Oil and Gas The oil and gas industry utilizes reflex rubber expansion joints to manage the demanding conditions of their transport systems effectively.

Conclusion

Reflex rubber expansion joints play an essential role in enhancing the performance and reliability of piping systems across various industries. Their unique design capabilities allow them to absorb movements, dampen vibrations, and mitigate stress on pipelines, contributing to the overall efficiency and longevity of industrial processes. As systems become increasingly complex and the demand for resilient infrastructure grows, reflex rubber expansion joints will continue to be a vital component in the pursuit of safe, efficient, and environmentally conscious operations.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025