Dec . 12, 2024 12:23 Back to list

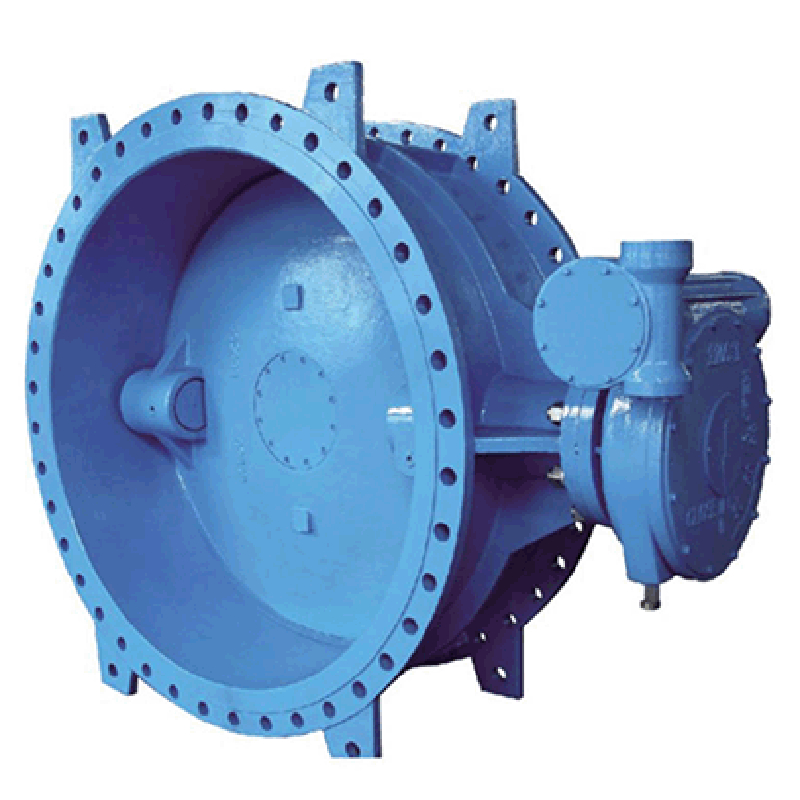

mss glove valve

Understanding MSS Glove Valves A Comprehensive Overview

In the realm of industrial equipment, valves play a crucial role in managing the flow of fluids—whether they are liquids or gases. Among the various types of valves, the glove valve, also known as a glove or glove-style valve, offers unique advantages particularly suitable for specific applications in handling corrosive or high-pressure fluids. This article delves into the concept of MSS glove valves, exploring their design, function, and significance in industrial operations.

What is a Glove Valve?

A glove valve is a type of linear motion valve used primarily to control the flow of media in pipelines. Its name is derived from its glove-like appearance, characterized by a disk or tapered plug that is raised or lowered to open or close the flow path. Unlike traditional valves, glove valves feature a simple mechanism that allows for precise control, making them suitable for applications requiring accurate flow regulation.

MSS Standards

The term MSS stands for the Manufacturers Standardization Society, which provides guidelines and specifications for various types of valves, fittings, and piping components in industrial applications. The MSS has established standards that ensure the quality, safety, and interoperability of these products. MSS glove valves adhere to these specifications, which guarantees their performance meets industry benchmarks.

Design and Construction

MSS glove valves are typically constructed from a range of materials including carbon steel, stainless steel, and various alloys, depending on the fluid's properties and the environmental conditions they will be exposed to. The design includes a body, a bonnet, a disk, and a stem, all of which work together to facilitate fluid control.

One of the key design features of glove valves is their ability to achieve tight sealing, which is critical in preventing leaks—especially when dealing with hazardous or expensive fluids. Additionally, the design is often enhanced with welded or threaded ends to facilitate seamless integration into existing pipeline systems.

Working Principle

The operation of an MSS glove valve is relatively straightforward. When the valve handle is turned, the attached stem moves the disk downwards, engaging it with the seat and thereby halting the flow of fluid. Conversely, lifting the disk allows fluid to pass through. This simple up-and-down motion not only simplifies the design but also enhances the valve's reliability and ease of maintenance.

mss glove valve

Advantages of MSS Glove Valves

1. Flow Control Glove valves provide excellent flow regulation, making them ideal for applications requiring precise control over fluid dynamics.

2. Sealing Ability The design allows for a tight seal, which is essential for preventing leaks, ensuring safety in operations dealing with hazardous materials.

3. Versatility These valves can handle a variety of fluid types, including gases, liquids, and slurries, making them versatile in different industrial sectors such as chemical processing, oil and gas, and water treatment.

4. Maintenance Glove valves are generally easy to maintain due to their uncomplicated design, reducing downtime and operational costs associated with valve replacement or repairs.

5. MSS Compliance Adhering to MSS standards ensures that the glove valves meet industry regulations and performance criteria, providing peace of mind for users.

Applications

MSS glove valves are utilized in numerous industries, including chemical manufacturing, pharmaceuticals, oil and gas, and wastewater management. Their ability to manage high-pressure environments and corrosive substances makes them indispensable in these sectors. Common applications involve controlling the flow of steam, chemicals, and water in processing plants, where precision and reliability are paramount.

Conclusion

MSS glove valves represent an essential category of valves in modern industry, characterized by their effective sealing, ease of maintenance, and precise flow control capabilities. By adhering to established MSS standards, manufacturers ensure that these valves meet rigorous quality expectations, enabling industries to operate safely and efficiently. As technology progresses, the design and functionality of MSS glove valves will continue to evolve, promising even greater performance in managing fluid dynamics in a variety of applications.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025