Dec . 05, 2024 15:00 Back to list

Low Pressure Check Valve Function and Applications in Fluid Systems

Understanding Low Pressure Check Valves Mechanism, Applications, and Importance

Low pressure check valves are vital components in various fluid systems, designed to allow flow in one direction while preventing backflow when the pressure drops. These valves are crucial for maintaining system integrity and efficiency in many applications, ranging from industrial processes to domestic plumbing. Understanding how they work, their applications, and their significance can help in choosing the appropriate valve for specific needs.

Mechanism of Low Pressure Check Valves

At the heart of a low pressure check valve is a simple yet effective mechanism that relies on pressure differentials. Typically, these valves consist of a valve body, an inlet and outlet port, and a movable disc or ball. When fluid flows through the valve in the intended direction, it pushes the disc or ball off its seat, allowing fluid to flow freely. However, when the flow reverses or the pressure drops below a certain threshold, the disc or ball returns to its seat, effectively sealing the valve and preventing backflow.

This one-way functionality is essential in preventing various issues such as siphoning of fluids, contamination, and equipment damage. Furthermore, check valves are designed to open and close quickly, ensuring that they respond promptly to changes in flow direction and pressure.

Applications

Low pressure check valves find a wide range of applications across different industries. Some common uses include

1. Water Treatment Plants In water treatment processes, low pressure check valves help maintain the direction of water flow, preventing contaminated water from flowing back into clean water systems.

2. HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, these valves ensure that coolant and heating fluids flow in the correct direction, improving system efficiency and preventing damage.

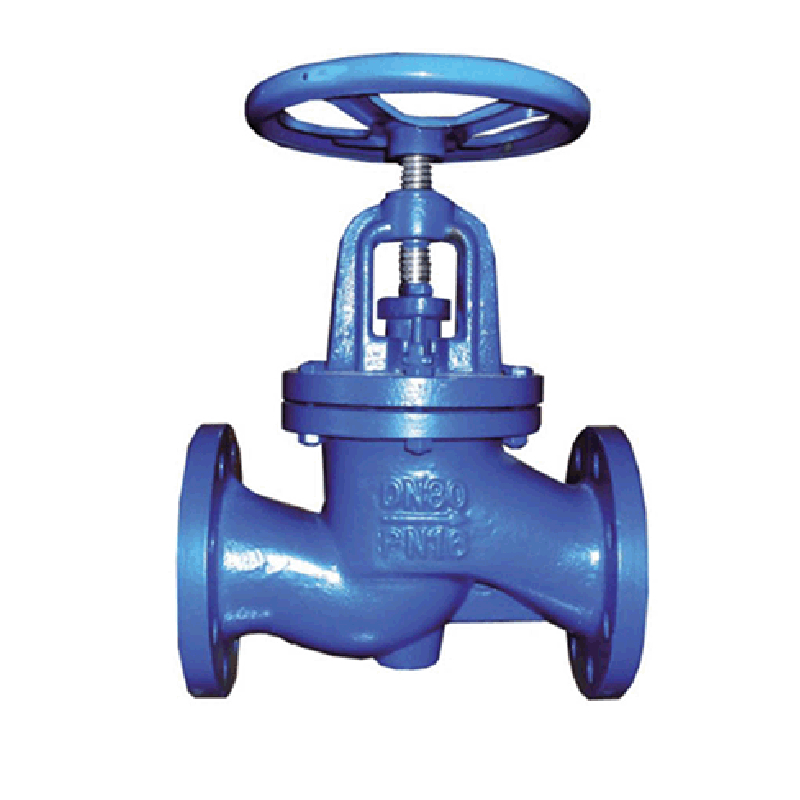

low pressure check valve

4. Irrigation Systems In agricultural applications, check valves prevent water from draining back into supply lines, ensuring efficient water usage in irrigation systems.

5. Chemical Processing The chemical industry often uses check valves to prevent the reverse flow of potentially hazardous chemicals, ensuring worker safety and system reliability.

Importance of Low Pressure Check Valves

The significance of low pressure check valves cannot be overstated. Here are several reasons highlighting their importance

1. System Protection By preventing backflow, these valves protect pumps, compressors, and other equipment from damage that can occur due to reverse flow. This protection can lead to reduced maintenance costs and extended equipment lifespan.

2. Efficiency Enhancement Low pressure check valves contribute to the overall efficiency of fluid systems. By maintaining the intended flow direction, they reduce energy consumption and minimize losses that can occur due to backtracking fluids.

3. Safety Assurance In many applications, particularly in chemical and water treatment processes, backflow can introduce contaminants or hazardous materials into clean systems. Low pressure check valves are critical for maintaining the safety and quality of fluids handled in these processes.

4. Cost-Effectiveness Investing in quality low pressure check valves can result in long-term cost savings. They help prevent operational downtimes, reduce repair or replacement costs, and enhance the overall reliability of fluid systems.

Conclusion

In summary, low pressure check valves are indispensable in various fluid handling applications. Their simple yet effective design plays a crucial role in ensuring the unidirectional flow of fluids, preventing backflow, and protecting equipment from damage. Whether in industrial settings, domestic plumbing, or agricultural systems, understanding the importance of these valves can help in making informed decisions regarding fluid system design and maintenance. As technology advances, innovations in valve design are likely to enhance their efficiency and functionality further, underscoring their significant role in modern engineering.

Share

-

Advanced Technology in Wire and Cable FactoryNewsAug.19,2025

-

Applications of Ball Check Valve in Water Treatment PlantsNewsAug.19,2025

-

How Osy Gate Valve Ensures Leak - Tight SealingNewsAug.19,2025

-

Selection Criteria for Wafer Type Butterfly ValveNewsAug.19,2025

-

Threaded Ball Valve Pressure RatingsNewsAug.19,2025

-

Y Strainer PN16 Cost - Effectiveness AnalysisNewsAug.19,2025