Dec . 05, 2024 14:36 Back to list

lever operated butterfly valve

Lever Operated Butterfly Valve An Overview

The lever operated butterfly valve is a vital component in various industrial applications, known for its simplicity, efficiency, and reliability. This type of valve employs a flat disc, known as a butterfly, which rotates about a central axis to control the flow of fluids in a pipeline. Lever operation adds a manual control option, enabling quick and easy adjustment of the valve’s position.

Design and Principles of Operation

A butterfly valve consists of several key components the body, the disc, the shaft, and the actuator. In a lever-operated configuration, the actuator is replaced with a lever that can be manually manipulated. The lever is attached to the shaft, which is connected to the disc. When the lever is turned, the disc rotates, opening or closing the flow path, allowing operators to regulate fluid flow effectively.

The design of a butterfly valve is inherently simple, making it lightweight and compact compared to other valve types, such as gate or globe valves. This compactness allows for easy installation in tight spaces, making the butterfly valve a preferred choice in various settings, including water treatment plants, chemical processing, and HVAC systems.

Advantages of Lever Operated Butterfly Valves

1. Ease of Use The lever operation provides a straightforward and intuitive means for operators to control the valve. This is particularly beneficial in situations where quick adjustments may be needed, such as during maintenance or in emergency conditions.

2. Space-Saving Design Due to their slim profile, lever operated butterfly valves are ideal for installations with limited space. Their lightweight nature also reduces the structural support required, further saving on installation costs.

3. Cost-Effective Butterfly valves are often more economical than other valve types due to their simple design and ease of manufacturing. The manual lever operation eliminates the need for complex actuators, contributing to overall cost savings.

lever operated butterfly valve

4. Versatility These valves can handle a variety of fluids, including gases, liquids, and slurries, making them suitable for an expansive range of applications across different industries.

5. Low Pressure Drop Butterfly valves typically exhibit a lower pressure drop compared to other valve types, which enhances flow efficiency and can lead to reduced energy consumption in pumping systems.

Applications

Lever operated butterfly valves find widespread use in various settings. In water treatment facilities, they regulate the flow of water through filtration and sedimentation processes. In the food and beverage industry, they control the flow of ingredients and ensure hygiene standards are met. Additionally, these valves are prevalent in HVAC systems for regulating airflow and temperature control.

Maintenance and Considerations

While generally low-maintenance, lever operated butterfly valves must be inspected regularly for wear and tear, especially on the sealing surfaces and the lever mechanism. Any signs of leakage or difficulty in operation should be addressed promptly to avoid system inefficiencies.

When selecting a lever operated butterfly valve, it’s essential to consider factors such as the size, pressure rating, and material compatibility with the fluids being handled. Choosing the right valve ensures optimal performance and longevity in the application.

Conclusion

In conclusion, lever operated butterfly valves are an essential part of fluid control systems in various industries. Their ease of use, cost-effectiveness, and versatile applications make them favorable for many operational needs. By understanding their design, advantages, and proper maintenance strategies, operators can ensure efficient and effective fluid flow management. Whether in water treatment, chemical processing, or HVAC systems, these valves play a critical role in the smooth operation of numerous processes.

Share

-

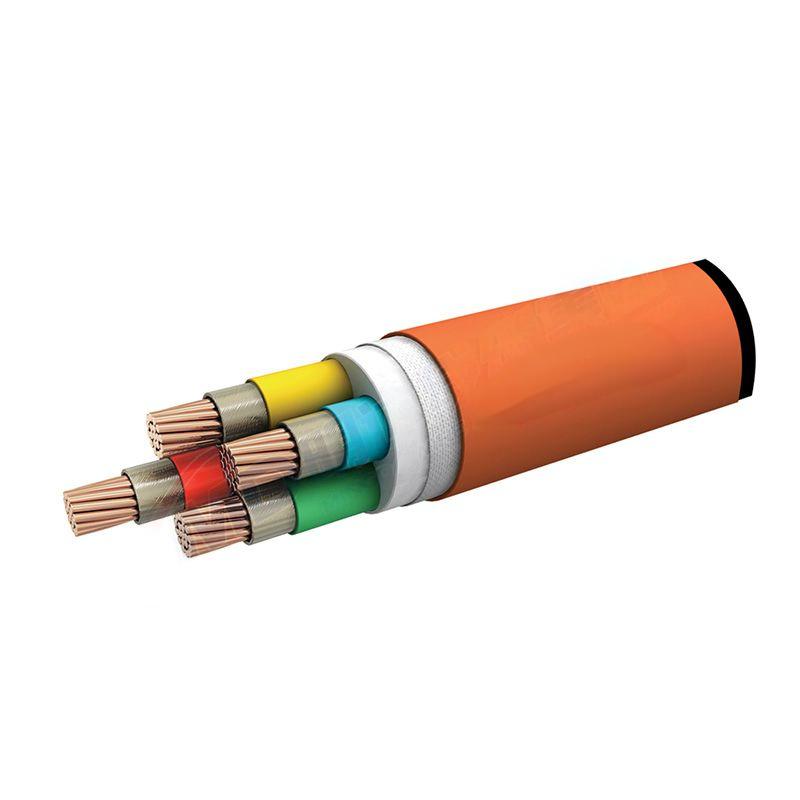

Advanced Technology in Wire and Cable FactoryNewsAug.19,2025

-

Applications of Ball Check Valve in Water Treatment PlantsNewsAug.19,2025

-

How Osy Gate Valve Ensures Leak - Tight SealingNewsAug.19,2025

-

Selection Criteria for Wafer Type Butterfly ValveNewsAug.19,2025

-

Threaded Ball Valve Pressure RatingsNewsAug.19,2025

-

Y Strainer PN16 Cost - Effectiveness AnalysisNewsAug.19,2025