Dec . 07, 2024 00:25 Back to list

Hydraulic Control Valve Operation and Applications in Fluid Management Systems

Understanding Hydraulic Control Valves Functionality and Applications

Hydraulic control valves are crucial components in hydraulic systems, playing a vital role in managing fluid flow and pressure within various machinery and equipment. These valves act as gatekeepers, regulating the movement of hydraulic fluid to ensure that machines operate smoothly and efficiently. This article delves into the functionality, types, and applications of hydraulic control valves to provide a comprehensive understanding of their significance in modern engineering.

Functionality of Hydraulic Control Valves

At its core, a hydraulic control valve is designed to direct fluid flow to different parts of a hydraulic system. By controlling the flow rate and pressure, these valves impact the speed and force of hydraulic actuators such as cylinders and motors. The primary functions of hydraulic control valves include

1. Flow Control Managing the velocity of fluid within a system. Flow control valves can either restrict or allow fluid passage based on operational requirements.

2. Pressure Control Maintaining system pressure within specified limits. Pressure relief valves prevent over-pressurization, protecting components from potential damage.

3. Directional Control Guiding hydraulic fluid to specific circuits in the system. Directional control valves determine the path the fluid will take, influencing machine movement such as lifting, tilting, or rotating.

4. Safety Functions Ensuring the safe operation of hydraulic systems. Various types of hydraulic control valves, such as lock valves, are designed to hold load in place and prevent accidents in case of power failure.

Types of Hydraulic Control Valves

Hydraulic control valves come in various types, each suited for specific applications. Some common types include

1. Directional Control Valves These valves manage the direction of fluid flow in a hydraulic system. They can be categorized based on their design, including spool valves and poppet valves, which either move mechanically or electrically to open or close pathways.

2. Flow Control Valves Implemented for regulating the fluid's flow rate, flow control valves can be adjustable or fixed. They often include throttling valves, which vary the flow by constricting or expanding the fluid's pathway.

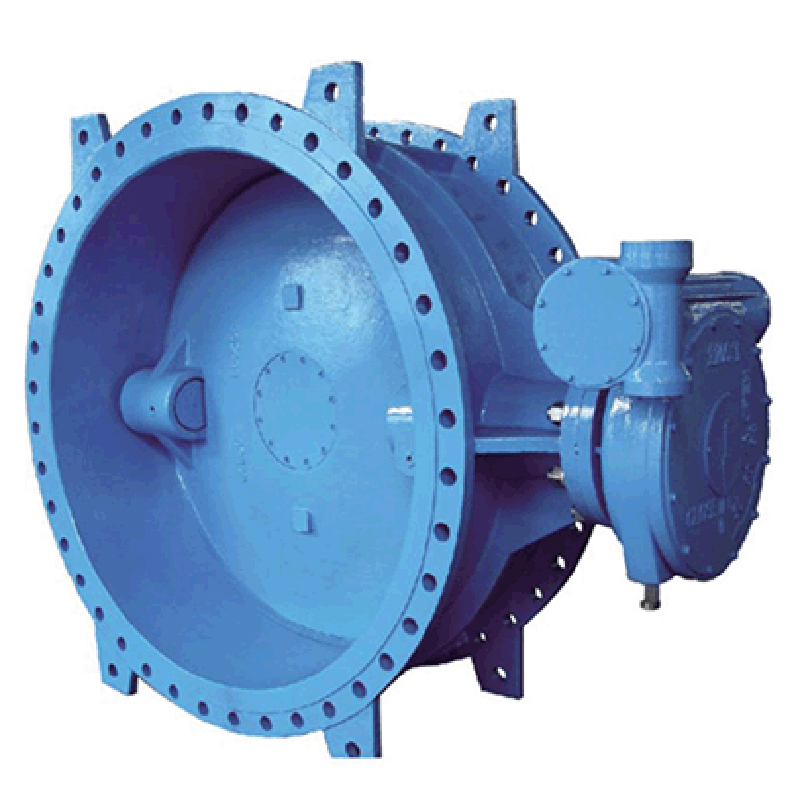

hydraulic control valve

3. Pressure Control Valves These valves help maintain proper pressure levels in systems. Common variants include relief valves, which release excess pressure, and reducing valves, which lower pressure to a desired level.

4. Check Valves Used to prevent backflow in hydraulic circuits, check valves ensure fluid flows in only one direction, protecting system integrity.

Each type of valve plays a unique role and is selected based on the requirements of the hydraulic system in which it is installed.

Applications of Hydraulic Control Valves

Hydraulic control valves find extensive applications across various industries. Some notable applications include

1. Construction Machinery In heavy-duty equipment such as excavators and bulldozers, hydraulic control valves ensure precise control of movements for digging, lifting, and other operations.

2. Manufacturing Equipment In automated assembly lines, hydraulic valves regulate the movement of press machines, robotic arms, and other machinery, enhancing production efficiency.

3. Automotive Industry Hydraulic control valves are integral to systems like braking and steering, ensuring responsiveness and safety in vehicles.

4. Agriculture Tractors and hydraulic implements utilize control valves to manage tasks like tilling and planting, improving operational effectiveness.

5. Aerospace In aviation, hydraulic systems controlled by valves operate landing gear, flight control surfaces, and brakes, emphasizing the importance of reliability and precision.

Conclusion

In summary, hydraulic control valves are essential components that enable the effective operation of hydraulic systems across diverse industries. By regulating fluid flow, pressure, and direction, these valves ensure machines function optimally and safely. Understanding their functionality and applications is critical for engineers and technicians involved in designing, maintaining, and operating hydraulic systems. As technology advances, the role of hydraulic control valves will continue to evolve, emphasizing the need for innovation in hydraulic system design and functionality.

Share