Nov . 19, 2024 17:05 Back to list

Electric Actuators for Gate Valves Efficient Control Solutions for Fluid Management

The Importance of Electric Gate Valve Actuators in Modern Industry

In contemporary industrial systems, the management and regulation of fluid flow are critical. Electric gate valve actuators play an essential role in ensuring efficiency, reliability, and precision in various applications, ranging from water treatment plants to oil and gas pipelines. This article explores the significance of these actuators, their functioning, advantages, and applications, underscoring their importance in modern engineering.

Electric gate valve actuators are devices responsible for automatically opening and closing gate valves using electric power instead of manual operation. They provide a precise control mechanism, allowing for efficient regulation of the flow of liquids and gases. The actuator converts electrical energy into mechanical motion, facilitating the operation of the gate valve. This automation is vital, especially in complex systems where manual operation would be impractical or unsafe.

One of the primary advantages of electric gate valve actuators is their ability to offer remote operation. This feature is particularly beneficial in large industrial plants where valves may be located in hard-to-reach areas. By integrating these actuators into a centralized control system, operators can monitor and control multiple valves from a single location, enhancing operational efficiency and safety. This remote capability is crucial during emergencies, allowing for quick responses without risking personnel safety.

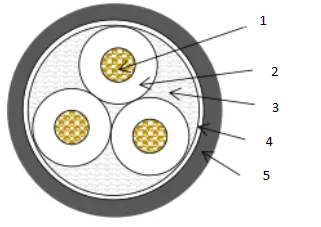

electric gate valve actuators

Another significant advantage of electric actuators is their accuracy. They provide precise control over valve positioning, which is essential for maintaining desired flow rates and pressure levels. This level of control minimizes the risk of over-pressurization or underflow, which can lead to catastrophic failures in systems. Electric actuators can be coupled with sensors and software systems to create feedback loops, ensuring that the valves operate within specified parameters at all times.

Furthermore, electric gate valve actuators are known for their low maintenance requirements compared to traditional pneumatic or hydraulic actuators. With fewer moving parts and no requirement for additional fluids, electric actuators present a more economical option over time. This reduced maintenance not only lowers operational costs but also minimizes downtime, a crucial factor in maintaining productivity in industrial operations.

Electric gate valve actuators are highly versatile and can be utilized in various sectors, including water and wastewater treatment, petrochemicals, pharmaceuticals, and food processing. For instance, in the wastewater treatment industry, these actuators are vital for controlling the flow of treated water and sludge, ensuring that processes operate smoothly and efficiently. In the pharmaceutical industry, precision and cleanliness are paramount; electric actuators help maintain the integrity of delicate processes.

In conclusion, electric gate valve actuators are integral components of modern industrial systems. Their ability to automate valve operations, ensure accurate flow control, and offer low maintenance makes them invaluable across various applications. As industries continue to evolve and seek greater efficiency and safety in their operations, the reliance on electric gate valve actuators will undoubtedly increase, paving the way for more advanced and streamlined processes. Their significance in enhancing productivity and operational effectiveness cannot be overstated, making them a cornerstone of contemporary industrial engineering.

Share

-

priming-a-pump-with-a-foot-valve-with-strainerNewsAug.23,2025

-

the-importance-of-a-y-strainer-in-pump-protectionNewsAug.23,2025

-

stainless-steel-ball-check-valve-for-high-purity-applicationsNewsAug.23,2025

-

common-applications-for-wafer-type-butterfly-valvesNewsAug.23,2025

-

seat-options-for-a-12-inch-knife-gate-valveNewsAug.23,2025

-

the-lifespan-of-a-typical-dismantling-jointNewsAug.23,2025