Nov . 14, 2024 20:41 Back to list

electric gate valve actuators

Electric Gate Valve Actuators A Key Component in Automated Control Systems

Electric gate valve actuators are pivotal devices in various industrial applications, providing essential functions for controlling the flow of fluids in pipelines. These actuators are specifically designed to operate gate valves, which are crucial for managing the on/off flow of liquid or gas through a system. With the rise of automation in industries such as oil and gas, water treatment, and chemical manufacturing, electric actuators have become indispensable for enhancing process efficiency, safety, and reliability.

Understanding Electric Gate Valve Actuators

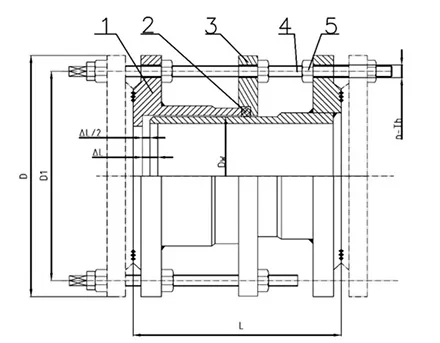

An electric gate valve actuator comprises several components, including an electric motor, a gear system, and a control mechanism. The electric motor drives the gear system, which then translates the rotational motion into linear motion to open or close the gate valve. This design allows for precise control over the valve position, enabling operators to manage flow rates effectively.

One of the main advantages of electric actuators over traditional pneumatic or hydraulic options is their efficiency and ease of integration with modern control systems. Electric actuators can be easily connected to programmable logic controllers (PLCs) or distributed control systems (DCS), allowing for remote operation and monitoring. This capability not only streamlines operations but also reduces the need for manual intervention, thus minimizing the risk of human error.

Benefits of Using Electric Actuators

1. Energy Efficiency Electric gate valve actuators consume less energy compared to their pneumatic or hydraulic counterparts. They can be powered via standard electrical outlets, making them more accessible and easier to install.

electric gate valve actuators

2. Maintenance-Free Operation Electric actuators require minimal maintenance, primarily due to their sturdy design and the absence of fluid leaks associated with hydraulic systems. This results in lower operational costs over the actuator's lifespan.

3. Precision Control The design of electric actuators allows for fine control over valve position, ensuring that operations can be adjusted precisely according to process requirements. This feature is particularly valuable in applications where flow rates must be carefully managed.

4. Safety Features Many electric actuators come equipped with advanced safety features, such as limit switches and feedback systems, which prevent the valve from operating beyond its designated range. This enhances the overall safety of the system, particularly in hazardous environments.

5. Versatility Electric gate valve actuators can be applied in a wide variety of industries and scenarios, from handling corrosive substances in chemical plants to controlling water flow in municipal systems.

Conclusion

In conclusion, electric gate valve actuators are essential components in contemporary industrial systems. Their energy efficiency, maintenance-free operation, and precision make them an attractive choice for businesses looking to optimize their operations and reduce costs. As industries continue to embrace automation, the role of electric actuators will only grow in significance, paving the way for more efficient and reliable fluid control solutions. By integrating these advanced devices into their systems, companies can not only enhance their operational capabilities but also promote a safer and more sustainable working environment. With continued advancements in technology, the future of electric gate valve actuators looks promising, poised to meet the evolving demands of industries worldwide.

Share