Jan . 06, 2025 18:44 Back to list

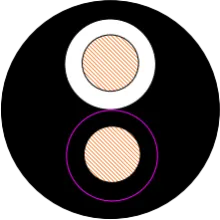

flange type butterfly valve

Butterfly valves are integral components in the world of fluid control, finding broad applications across various industries such as water treatment, chemical processing, and oil and gas. These devices, characterized by their quarter-turn rotation and disc-shaped closure, offer notable advantages in regulating flow, ensuring efficient operation under a variety of conditions.

The defining feature of a butterfly valve is its simplistic yet effective design, which consists of a disc that rotates on a central axis. This construction allows for swift operation with minimal effort, resulting in reduced energy consumption and lower operational costs. Unlike traditional gate or globe valves, butterfly valves provide a reliable, maintenance-friendly solution. With less mechanical wear and tear and fewer components, they minimize downtime, ensuring sustained productivity.

From an expert perspective, choosing the right butterfly valve for a specific application requires comprehensive understanding beyond mere compatibility checks. Material selection plays a pivotal role, ensuring durability and resistance to the medium being controlled. For instance, valves constructed with stainless steel or high-performance alloys like Hastelloy are preferred in corrosive environments due to their resistance to chemical reactions. In contrast, ductile iron-based valves may fit scenarios where temperature and pressure requirements are moderate. Understanding these nuances requires not only technical knowledge but also an experienced evaluation of the operational demands and environmental conditions the valve will encounter.

In addition to material considerations, understanding the operational parameters is crucial. A valve's pressure rating and temperature capabilities must align with the system requirements to avoid failures. Manufacturers often provide detailed specifications concerning their products, and scrutinizing these can ensure appropriate selection and application. Application engineers and procurement specialists, armed with extensive field experience, can offer invaluable insights into making informed decisions that blend safety, efficiency, and cost-effectiveness.

Beyond selection and installation, maintenance practices significantly impact the performance and lifespan of butterfly valves. A regimented maintenance schedule, involving routine inspections, fixation of loose components, and replacement of wear-prone parts like seals, extends operational life. By investing in preventive care rather than reactive maintenance, industries can guarantee continuous performance, mitigating risks associated with unscheduled downtimes.

butterfly valve

Trust in manufacturers and suppliers establishes another layer of reliability. Partnering with industry leaders known for innovation and quality assurance, such as those who comply with international standard certifications like ISO or API, enhances trustworthiness in product procurement. Additionally, seeking out brands that offer comprehensive support and training empowers users, ensuring optimal use and adherence to best practices.

In the technological era, integration with automation systems further elevates the functionality of butterfly valves. Smart technology solutions allow for real-time monitoring and control, significantly boosting process efficiency and responsiveness. Valves equipped with intelligent sensors and actuators can self-adjust to variances in flow, paving the path towards smart industry and aligning with modern industrial 4.0 paradigms.

Finally, as global emphasis shifts towards sustainability, butterfly valves remain at the forefront of implementing eco-friendly practices. Their enhanced controllability optimizes resource use, reducing waste and subsequently environmental impact. Industries prioritizing sustainability can leverage the advancements in butterfly valve technologies to support green initiatives, contributing positively to the global sustainability goals.

In summary, butterfly valves, with their robust design and adaptability, anchor themselves as essential components in fluid control systems. A sophisticated understanding of their properties, expert selection, rigorous upkeep, and trust in reputable manufacturers culminate in a powerful blend of efficiency, reliability, and sustainability.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025