Sep . 23, 2024 10:57 Back to list

Flanged Ball Valve Types and Their Applications in Industrial Settings

Understanding Ball Valve Flange Types

Ball valves are essential components in various piping systems, serving as on/off control devices that help regulate the flow of liquids and gases. Among the diverse range of ball valves available, flange types are particularly significant due to their robust design and ability to create leak-proof connections. In this article, we will explore the characteristics, advantages, and applications of ball valve flange types.

What is a Ball Valve Flange Type?

Flanged ball valves feature a design that allows them to be mounted between two flanges in a piping system. This configuration employs a flange that possesses raised edges to facilitate a secure connection with the pipes. The flanges are typically bolted together using bolts and nuts, ensuring that the valve remains firmly in place and prevents any leakage.

Key Characteristics

1. Material Composition Flanged ball valves are made from various materials, including stainless steel, carbon steel, and PVC, offering different characteristics suitable for various applications. For instance, stainless steel flanged ball valves are often used in corrosive environments due to their resistance to rust and chemical deterioration.

2. Pressure Ratings These valves come with different pressure ratings, allowing them to withstand varying levels of operational pressure in fluid systems. Common pressure ratings include 150 PSI, 300 PSI, and 600 PSI. The selection of the appropriate pressure rating is crucial for ensuring the reliable performance of the valve in specific applications.

3. Size Range Flanged ball valves are available in a wide range of sizes, from small diameters suitable for residential applications to large diameters for industrial processes. This flexibility ensures that they can be used in different types of piping systems seamlessly.

4. Actuation Options Flanged ball valves can be operated manually using a lever or can be automated using actuators. Electric or pneumatic actuators provide remote operation capabilities, making them suitable for applications requiring minimal human intervention.

Advantages of Flanged Ball Valves

- Ease of Installation The flanged design simplifies the installation process, allowing for easier alignment with the piping system. The robust nature of the bolted connection ensures a secure fit.

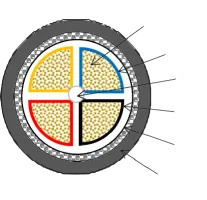

ball valve flange type

- Leak Prevention The gasket between the flanges provides an additional layer of sealing, significantly reducing the chances of leaks. This is particularly important in systems where leaks can lead to safety hazards or environmental concerns.

- Full-Flow Design Unlike some other valve types, flanged ball valves offer a straight-through flow path, minimizing turbulence and pressure loss. This design enhances the efficiency of fluid transport within the system.

- Versatility Flanged ball valves can handle a variety of fluids, including water, oil, gases, and more. Their adaptability makes them suitable for various industrial sectors, including oil and gas, chemical processing, and water treatment.

Applications of Flanged Ball Valves

Flanged ball valves are widely used in numerous industries due to their effective flow control capabilities. Some common applications include

- Oil and Gas In the oil and gas industry, flanged ball valves are used to manage the flow of crude oil and natural gas in pipelines.

- Chemical Processing These valves control the flow of chemicals in processing plants, where material compatibility and leak prevention are crucial.

- Water Treatment Flanged ball valves are implemented in municipal water systems for regulating water supply and managing waste.

- Power Generation In power plants, flanged ball valves control steam and water flow, critical for energy production.

Conclusion

In summary, ball valve flange types are integral to modern piping systems, providing reliable flow control, ease of installation, and leak prevention. With their diverse range of materials, pressure ratings, and sizes, these valves cater to various industries and applications. Understanding the features and advantages of flanged ball valves is essential for making informed decisions when selecting the appropriate valve for any piping system. As industries continue to evolve, the demand for effective and efficient flow control solutions like flanged ball valves will undoubtedly grow, reinforcing their importance in engineering and manufacturing sectors.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025