Nov . 08, 2024 18:39 Back to list

ball valve 2 inch

Understanding 2-Inch Ball Valves A Comprehensive Overview

When it comes to controlling the flow of liquids and gases in various industrial applications, ball valves are one of the most commonly used types of valves. Among these, the 2-inch ball valve stands out due to its versatility, efficiency, and reliability. In this article, we will delve into the features, applications, advantages, and maintenance of 2-inch ball valves.

What is a Ball Valve?

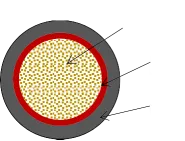

A ball valve is a type of valve that uses a spherical obstruction (the ball) to stop or allow fluid flow. The ball has a hole through its center, which allows the fluid to flow when the valve is open. When the valve is closed, the ball rotates 90 degrees to block the flow. This simple yet effective design provides excellent sealing capabilities, making ball valves suitable for various applications.

Key Features of 2-Inch Ball Valves

1. Size and Port Type A 2-inch ball valve has a nominal diameter of two inches, making it ideal for medium to large piping systems. They are available in full port and reduced port variations. Full port valves have a larger opening, allowing for better flow rates and reduced pressure drops.

2. Materials The construction material of the ball valve significantly influences its application. Common materials include brass, stainless steel, and PVC. Stainless steel is favored in corrosive environments, while PVC is often used in chemical applications.

3. Actuation Options 2-inch ball valves can be operated manually with a lever handle or automatically using electric, pneumatic, or hydraulic actuators. Automated valves are particularly useful in large-scale industrial processes where remote operation is required.

4. Temperature and Pressure Ratings These valves can handle a wide range of temperatures and pressures, making them suitable for various applications. It's essential to select a valve rated for the specific temperature and pressure of the system it will be used in.

Applications of 2-Inch Ball Valves

2-inch ball valves are employed in various industries due to their robust design and functionality. Some common applications include

- Water Supply Systems Ball valves control water flow in pipelines, irrigation systems, and municipal water supplies. - Oil and Gas Industry They are used in upstream and downstream applications to control the flow of crude oil, natural gas, and other hydrocarbons.

- Chemical Processing In this sector, 2-inch ball valves manage the flow of liquids and gases during chemical reactions, storage, and transportation.

- HVAC Systems Ball valves regulate the flow of chilled or heated water in heating, ventilation, and air conditioning applications.

Advantages of 2-Inch Ball Valves

ball valve 2 inch

The popularity of 2-inch ball valves can be attributed to several key advantages

2. Durability Made from robust materials, ball valves are resistant to wear and tear, providing longevity even under harsh conditions.

3. Quick Operation The 90-degree turn design allows for rapid opening and closing of the valve, enabling effective and immediate flow control.

4. Leak-Proof Sealing The design of the ball and the seals ensures that these valves are leak-proof when closed, enhancing safety in fluid transport.

5. Versatility With multiple actuation options and material choices, 2-inch ball valves can be tailored to suit specific operational needs.

Maintenance of 2-Inch Ball Valves

Proper maintenance is essential to ensure the longevity and efficiency of 2-inch ball valves. Here are a few tips

1. Regular Inspection Periodically check for leaks, wear, and corrosion. Addressing any issues early can prevent costly repairs.

2. Lubrication Regularly lubricating the valve’s moving parts can enhance performance and prevent sticking.

3. Actuator Maintenance For automated valves, ensure that actuators are functioning correctly and are well-maintained to ensure reliable operation.

4. Operational Testing Regularly test the valve’s operation to ensure that it opens and closes smoothly and that the sealing mechanism is intact.

Conclusion

In summary, 2-inch ball valves are essential components in various industrial applications due to their efficiency, durability, and versatility. Understanding their features, applications, and maintenance requirements can help industries optimize their operations and ensure safe fluid handling. Whether in water supply systems or chemical processing plants, the reliability of a 2-inch ball valve cannot be overstated. Investing in high-quality ball valves and adhering to regular maintenance practices will ultimately improve system performance and extend the life of your piping infrastructure.

Share