lis . 05, 2024 18:09 Back to list

silent wafer check valve

Understanding Silent Wafer Check Valves A Comprehensive Overview

Silent wafer check valves are essential components used in various plumbing and industrial applications to control the flow of fluids while preventing backflow. These valves play a crucial role in ensuring the efficiency and safety of fluid transport systems. In this article, we will delve into what silent wafer check valves are, how they function, their advantages, and common applications.

What is a Silent Wafer Check Valve?

A silent wafer check valve is a type of check valve that is designed to allow fluid to flow in one direction while preventing backflow in a quiet and efficient manner. Unlike traditional check valves that may produce noise during their operation, silent wafer check valves are engineered to minimize water hammer— a phenomenon caused by sudden changes in fluid flow that can lead to loud banging noises in pipes.

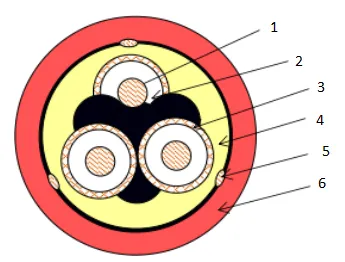

Typically, these valves are constructed from durable materials such as stainless steel, brass, or PVC, depending on the application requirements. Their wafer design allows for easy installation between flanges in pipelines, making them a popular choice for various industries.

How Do Silent Wafer Check Valves Work?

Silent wafer check valves use a simple yet effective mechanism to function. The valve comprises a disc or flap that is held in place by a spring or gravity. When fluid flows in the designated direction, the force of the moving fluid pushes the disc open, allowing the fluid to pass through. Conversely, if the fluid attempts to flow back in the opposite direction, the disc closes tightly against the valve seat, thus preventing backflow.

The key feature that distinguishes silent wafer check valves from standard check valves is their design that minimizes turbulence and noise during the flow of fluids. This is achieved through the use of specially designed discs that open and close smoothly.

Advantages of Silent Wafer Check Valves

1. Noise Reduction As the name suggests, silent wafer check valves generate minimal noise compared to traditional check valves. This is particularly beneficial in residential or noise-sensitive environments.

silent wafer check valve

2. Space Efficiency Their wafer design allows these valves to be installed between flanges, making them suitable for space-constrained applications without compromising on performance.

3. Durability Made with high-quality materials, silent wafer check valves are resistant to corrosion and wear, ensuring a long lifespan and reliability in various operating conditions.

4. Low Maintenance These valves require minimal maintenance, which reduces overall operational costs and downtime for inspections and repairs.

5. Versatility Silent wafer check valves can be used in a variety of applications such as water supply systems, HVAC systems, and industrial processes involving both liquids and gases.

Common Applications

Silent wafer check valves are utilized across numerous industries due to their effectiveness and reliability. Some common applications include

- Municipal Water Supply To prevent backflow and ensure the safety of drinking water. - Wastewater Management In sewage treatment plants to control flow and prevent contamination. - HVAC Systems For maintaining efficient heating and cooling cycles without noise disruption. - Fire Protection Systems To ensure effective water pressure and flow in firefighting applications. - Food and Beverage Industry To maintain product purity and avoid contamination during fluid transfer.

Conclusion

Silent wafer check valves are an indispensable part of modern fluid control systems. Their innovative design not only prevents backflow efficiently but also enhances the overall quietness of fluid transport. As industries continue to prioritize efficiency and safety, the adoption of silent wafer check valves will undoubtedly grow, solidifying their place in diverse applications. Understanding their functionality and benefits is essential for engineers and decision-makers who seek to optimize operational processes while ensuring reliability and compliance with industry standards.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025