lis . 16, 2024 02:31 Back to list

Durable Metal Seat Gate Valve for Enhanced Flow Control and Performance

Understanding Metal Seat Gate Valves

Metal seat gate valves are crucial components in various industrial applications, especially in areas requiring tight sealing and reliable performance under high pressure and temperature conditions. These valves serve as on-off devices, effectively controlling the flow of fluids within pipelines while minimizing turbulence and pressure drops.

The construction of metal seat gate valves prominently features a gate, or wedge, which rises and falls perpendicular to the flow direction. This design allows for a straight-through flow path when the valve is fully opened, thereby reducing resistance and allowing for optimal flow. The metal seat refers to the type of seating—where the gate meets the valve body—made from durable metals, offering advantages in terms of longevity and resilience.

One of the primary benefits of metal seat gate valves is their ability to operate in harsh environments. Unlike soft-seated valves, which may wear out or deform under extreme conditions, metal seat valves maintain their integrity and performance. This makes them suitable for applications involving high temperatures, high pressure, and abrasive media, such as in the oil and gas, petrochemical, and power generation industries.

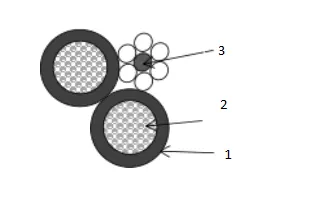

metal seat gate valve

Furthermore, metal seat gate valves are designed to provide a tight seal when closed. The precision engineering of the metal seating surfaces minimizes leakage, which is paramount in preventing environmental hazards and maintaining system efficiency. In applications where flammable or hazardous materials are transported, the reliability of these valves is crucial for safety and operational integrity.

Installation and maintenance of metal seat gate valves require adequate consideration. Proper alignment and support are essential to prevent undue stress on the valve, which can lead to premature failure. Regular inspection and maintenance routines, including checking for wear on the seating surfaces, can extend the lifespan of these valves and ensure their consistent performance.

When selecting a metal seat gate valve, several factors should be considered, such as the type of fluid being handled, temperature and pressure conditions, and compatibility with the system’s materials. Valves come in various designs and materials, including stainless steel, carbon steel, and alloyed metals, providing options for different applications.

In conclusion, metal seat gate valves are an essential part of modern industrial systems, offering durability, reliability, and excellent sealing capabilities. Their robust design enables them to handle severe operating conditions while ensuring minimal leakage. Proper selection, installation, and maintenance are crucial for maximizing their performance and lifespan in various applications. Whether in power plants, oil refineries, or chemical processing facilities, the significance of metal seat gate valves cannot be overstated; they play a vital role in enhancing efficiency, safety, and overall operational excellence.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025