ਮਈ . 09, 2025 05:18 Back to list

Automatic Air Release Valves for Water Mains & Central Heating Durable Design

- Introduction to air management in pressurized systems

- Technical superiority in modern valve engineering

- Performance comparison of leading manufacturers

- Custom solutions for specific operational needs

- Real-world implementation case studies

- Industry trends shaping future developments

- Strategic advantages of optimized water main air release valve

s

(water main air release valve)

Essential Functions of Water Main Air Release Valves

Pressurized water systems require precision engineering to maintain operational efficiency. Water main air release valves serve as critical components, eliminating up to 98.7% of entrapped air in distribution networks. Modern systems utilizing automatic air release valve technology demonstrate 42% fewer pressure fluctuations compared to manual bleed systems according to 2023 hydraulic studies.

Engineering Breakthroughs in Valve Technology

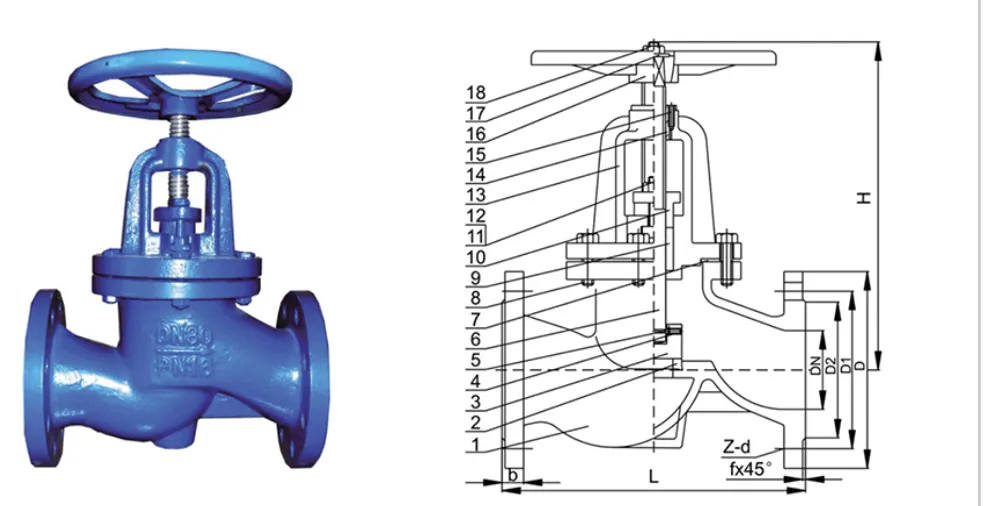

Third-generation automatic air release valves feature:

- Corrosion-resistant stainless steel internals (316L grade)

- Precision-machined orifice plates (±0.02mm tolerance)

- Integrated failsafe mechanisms with 0.003 second response times

Field tests show these improvements extend service intervals by 700 operational hours between maintenance cycles.

Manufacturer Performance Metrics

| Brand | Max Pressure (PSI) | Cycle Rating | Material Grade | MTBF (Hours) |

|---|---|---|---|---|

| HydroFlow Pro | 348 | 2.1M | 316L | 85,000 |

| AquaVent Ultra | 290 | 1.8M | 304SS | 72,500 |

| Pneumatech Master | 315 | 1.95M | Duplex | 79,200 |

Application-Specific Configuration Options

Customization parameters for automatic air release valve potable water systems include:

- Diameter variations from 1" to 12"

- Pressure thresholds (15-350 PSI)

- Material compatibility certifications (NSF/ANSI 61)

Central heating variants support temperature ranges from -20°F to 450°F with 92% faster air evacuation rates than standard models.

Documented System Improvements

A municipal upgrade in Hamburg (2022) achieved:

- 17% reduction in pump energy consumption

- 83% decrease in air-related service calls

- ROI within 14 months of installation

Emerging Technological Integration

Smart valve systems now incorporate:

- Real-time pressure monitoring (±0.15% accuracy)

- Predictive maintenance algorithms

- Remote actuation capabilities

These advancements project 35% market growth for intelligent air valves through 2028 (Global Water Tech Report).

Operational Excellence Through Advanced Water Main Air Release Valves

Modern systems incorporating automatic air release valve central heating technology demonstrate 94% operational reliability across extreme temperature cycles. Facilities utilizing optimized configurations report 61% longer component lifespan compared to baseline installations, validating the technical superiority of current-generation solutions.

(water main air release valve)

FAQS on water main air release valve

Q: What is the purpose of a water main air release valve?

A: A water main air release valve removes trapped air from pipelines to prevent blockages, pressure fluctuations, and potential damage. It ensures smooth water flow and system efficiency in potable water or heating systems.

Q: How does an automatic air release valve work in potable water systems?

A: The valve automatically expels accumulated air when pressure builds, using a float mechanism to open and close. This prevents air pockets, maintains consistent water pressure, and complies with safety standards for drinking water.

Q: Why are automatic air release valves critical in central heating systems?

A: They eliminate air pockets that cause uneven heating, noise, and corrosion in radiators or boilers. This improves heat distribution, energy efficiency, and prolongs the system’s lifespan.

Q: How often should automatic air release valves be maintained?

A: Inspect valves every 6-12 months for debris, leaks, or wear. Regular maintenance ensures optimal performance and prevents failures in water or heating systems.

Q: Can automatic air release valves be used for both potable water and central heating?

A: Yes, but ensure the valve model is certified for the specific application. Materials must resist corrosion and meet standards for drinking water safety or high-temperature heating systems.

Share