ਅਕਤੂਃ . 31, 2024 01:23 Back to list

wafer style butterfly valve

The Wafer Style Butterfly Valve An Essential Component in Fluid Control

The wafer style butterfly valve is a crucial component in the realm of fluid control, especially in the fields of water distribution, chemical processing, and HVAC systems. Known for its simple design and effective functionality, this type of valve is widely used across various industrial applications due to its remarkable advantages and versatility.

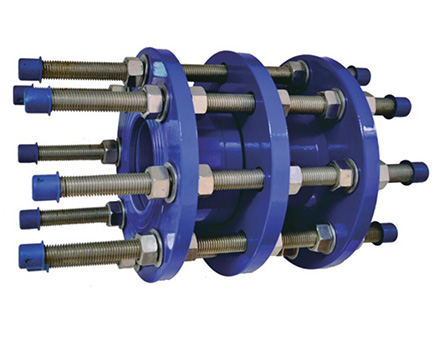

At its core, the wafer style butterfly valve consists of a circular disc or vane, which is pivoted on a shaft. This disc can rotate from a fully closed position to a fully open position, regulating the flow of fluid through the pipe effectively. The term wafer style indicates that the valve is designed to fit between two flanges in a piping system, creating a compact and lightweight solution for many piping configurations. This design simplifies installation and reduces the need for extra support, making it an economical choice for many engineers.

One of the primary advantages of wafer style butterfly valves is their minimal pressure drop when fully opened

. Unlike other types of valves, such as globe valves or gate valves, the streamlined disc allows for smooth passage of fluids, which is especially beneficial in systems where maintaining pressure is crucial. This characteristic makes wafer-style butterfly valves suitable for a wide range of flow conditions, from throttling to on/off control.wafer style butterfly valve

Another noteworthy feature of wafer style butterfly valves is their quick operation. The valve can be opened or closed with just a quarter turn of the actuator, making it highly efficient in applications requiring rapid response times. This quick actuation not only enhances operational efficiency but also contributes to safety in systems that need to regulate flow swiftly in case of a malfunction or emergency.

In terms of construction, wafer style butterfly valves can be manufactured from various materials such as cast iron, stainless steel, and plastic. The choice of material often depends on the application and the type of fluid being handled, whether corrosive, high-temperature, or abrasive. Furthermore, these valves can be equipped with different seat materials that enhance sealing performance and prolong service life.

Nevertheless, users should be aware of the limitations of wafer style butterfly valves. While they excel in many applications, they may not be suitable for all types of services, particularly where full shut-off is crucial. In conditions with high pressure or vacuum, more robust valve types may be required to ensure reliable performance.

In conclusion, the wafer style butterfly valve stands out as an essential device in modern fluid control systems. Its advantageous features, including low pressure drop, quick actuation, and adaptability to various environments, make it a preferred choice for engineers and operators alike. As industries continue to evolve, the importance of reliable and efficient components like the wafer style butterfly valve will only grow, ensuring optimal performance across numerous applications.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025