ਨਵੰ. . 22, 2024 05:12 Back to list

vnidirectional knife gate valve

Understanding Unidirectional Knife Gate Valves

Unidirectional knife gate valves are specialized industrial components designed for controlling the flow of liquids and slurries in various applications. These valves are particularly effective in handling thick, abrasive materials that would otherwise cause damage to traditional valves. Their unique design and operational capabilities make them suitable for a range of industries, including wastewater treatment, mining, and pulp and paper manufacturing.

Design and Functionality

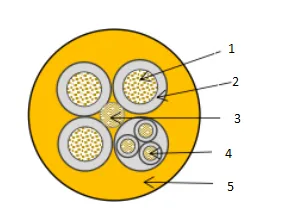

The knife gate valve operates on a straightforward principle a sharp-edged gate is lowered or raised to control flow. Unlike conventional valves that use a rotating mechanism, the knife gate’s design allows it to slice through accumulated debris or solid particles in the line, thus ensuring a reliable seal and flow control. This feature is particularly important in applications where materials might settle and create blockages.

Unidirectional knife gate valves are built to allow flow in one direction, reducing the risk of backflow and enhancing the efficiency of the system. Their structure typically includes a gate that is made from strong materials such as stainless steel or cast iron, which provides durability and resistance to wear and tear. By implementing a unidirectional design, these valves are ideal for industries that prioritize flow integrity and require robust solutions to manage heavy materials.

Advantages

One of the main advantages of unidirectional knife gate valves is their low maintenance requirements. Their simple design minimizes the number of moving parts, reducing the potential for mechanical failure. Additionally, the ability to cut through tough materials prevents clogging and prolongs the valve's operational life. This cost-effectiveness makes them a preferred choice in facilities where maintenance downtime can lead to significant productivity losses.

vnidirectional knife gate valve

Moreover, these valves can be outfitted with various actuators, including manual, pneumatic, or electric systems, facilitating integration into automated processes. Operators can easily control and monitor flow rates, enhancing overall system efficiency and reliability.

Applications

Unidirectional knife gate valves are utilized across a wide range of sectors. In the waste treatment industry, they manage the flow of sludge and other viscous materials, ensuring consistent operation of treatment systems. The mining industry benefits from their ability to handle slurries containing high solid content, while the pulp and paper industry uses them to regulate the flow of fiber suspensions.

These valves are also gaining popularity in food processing applications, as their design minimizes contamination risks and allows for easy cleaning. The versatility and efficiency of unidirectional knife gate valves position them as essential components in modern industrial operations.

Conclusion

In summary, unidirectional knife gate valves are crucial for managing the flow of abrasive and viscous materials in various industries. Their robust design, ease of maintenance, and ability to prevent backflow make them invaluable in applications where efficiency and reliability are paramount. As industries continue to evolve, the role of these valves in optimizing processes and ensuring safe operations will only grow more significant.

Share

-

YType Strainer: Reliable guardians in fluid pipelinesNewsMay.15,2025

-

Wire Cable: The invisible pillar of engineering strengthNewsMay.15,2025

-

Wafer Type Butterfly Valve Flange: Characteristics, Applications, and Development TrendsNewsMay.15,2025

-

Standard Wire and Cable: Building the nervous system of modern societyNewsMay.15,2025

-

RSV Gate Valves: Structure, Application, and Analysis of Advantages and DisadvantagesNewsMay.15,2025

-

NonReturn Swing Check Valve: A reliable unidirectional flow control deviceNewsMay.15,2025