ਦਸੰ. . 09, 2024 19:15 Back to list

Pneumatic Actuated Ball Valve for Efficient Fluid Control Solutions in Industrial Applications

Understanding Pneumatic Ball Valves Design, Function, and Applications

Pneumatic ball valves are critical components in a variety of industrial applications, providing reliable flow control for gases and liquids. These valves utilize a spherical disc, also known as a ball, which serves as the closure element. The ball features a hole through its center, and when aligned with the flow direction, the valve is open; when rotated 90 degrees, the flow is blocked. This simple yet effective mechanism makes pneumatic ball valves a popular choice in many sectors, including manufacturing, chemical processing, and HVAC systems.

Design and Construction

The design of a pneumatic ball valve is defined by its straightforward functionality and robust construction. The primary components include the valve body, the ball, the seats, and the actuator.

- Valve Body Typically made from durable materials such as stainless steel, brass, or plastic, the valve body houses the ball and provides structural integrity. - Ball The ball is often constructed from similar materials to the valve body, ensuring a good match for pressure and temperature conditions. The ball's smooth surface reduces friction and wear over time, contributing to the valve's longevity.

- Seats These are the sealing surfaces that ensure a tight fit between the ball and the valve body when the valve is closed. Materials like PTFE or other elastomers are frequently used for their chemical resistance and ability to achieve a reliable seal.

- Actuator The actuator is the mechanism that opens and closes the valve. In pneumatic ball valves, this is typically a pneumatic actuator that uses compressed air to create motion. The actuator can be configured as either a spring return or double-acting system, allowing for precise control over valve positioning.

Working Principle

The operation of a pneumatic ball valve is relatively straightforward. When pneumatic pressure is applied to the actuator, it rotates the ball within the valve body. In its open position, the flow is unrestricted, allowing for efficient fluid conveyance. When pressure is released or the actuator is activated in the opposite direction, the ball turns to block the flow, effectively shutting off the process.

This capability of rapid open and close cycles makes pneumatic ball valves suitable for applications that require quick response times. Additionally, they are capable of handling significant pressure and flow rates, making them versatile in various settings.

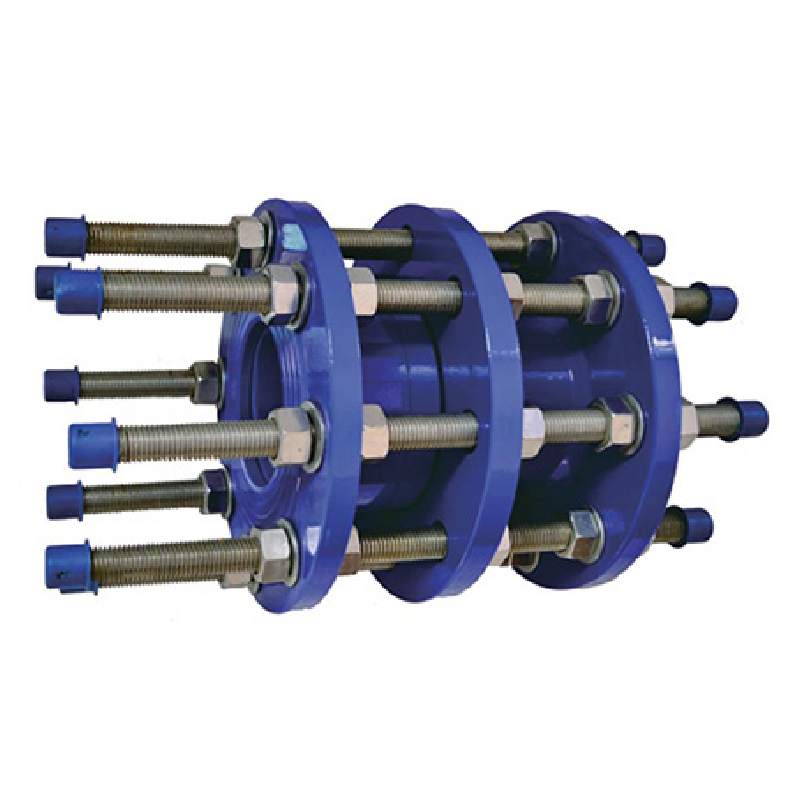

pneumatic ball valve

Applications

Pneumatic ball valves are widely used across many industries due to their reliability and efficiency. Some common applications include

- Chemical Processing In environments where corrosive substances are handled, pneumatic ball valves offer excellent resistance to chemical reactions and wear, ensuring safe and reliable flow control.

- Water and Wastewater Treatment These valves are crucial in managing the flow of water through treatment plants and systems, allowing operators to open or shut down pipelines with ease.

- Oil and Gas Industry In the oil and gas sector, where precise flow management is essential, pneumatic ball valves handle high-pressure applications, regulating the flow of crude oil and natural gas.

- Food and Beverage Sanitary designs of pneumatic ball valves ensure compliance with health regulations while maintaining the efficiency of processing systems.

Advantages of Pneumatic Ball Valves

The advantages of using pneumatic ball valves are numerous. Their design allows for quick actuation, reducing downtime in industrial processes. The low torque requirement for operation means that even small actuators can handle larger valves, optimizing energy use. Additionally, the straightforward construction facilitates easy maintenance and replacement, leading to lower operational costs over time.

Conclusion

Pneumatic ball valves play an essential role in modern industrial automation and fluid control. Their reliable performance, ease of use, and versatility across various applications make them a favored choice for engineers and operators alike. Understanding the design, operation, and benefits of these valves can help industries optimize their processes, enhancing safety and efficiency in fluid management systems. As technology evolves, so too does the potential for pneumatic ball valves to meet the growing demands of industries worldwide.

Share