ਨਵੰ. . 17, 2024 00:56 Back to list

industrial gate valve

The Significance of Industrial Gate Valves in Modern Applications

Industrial gate valves are essential components in various piping systems, used primarily to control the flow of liquids and gases. These valves operate by lifting a rectangular or circular gate out of the fluid path, offering a straight-through passage that minimizes pressure loss when fully open. This design minimizes turbulence, making gate valves particularly popular in applications where flow efficiency is crucial.

Design and Functionality

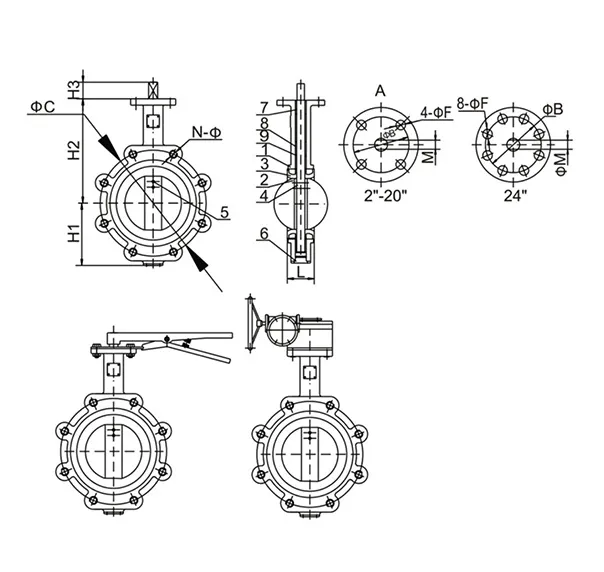

Gate valves come in various designs, including rising stem and non-rising stem configurations. The rising stem gate valve features a stem that rises and falls with the gate, providing an easy visual indication of the valve's position. In contrast, non-rising stem designs are preferred in situations where space constraints are an issue, as the stem remains stationary while the gate moves.

Materials used in gate valve construction vary depending on the application. Common materials include cast iron, stainless steel, bronze, and other alloys that offer resistance to corrosion, wear, and temperature fluctuations. This versatility in materials ensures that industrial gate valves can be adapted to suit many environments, whether it be the harsh conditions of a mining operation or the sterile settings of food processing.

Applications of Industrial Gate Valves

Industrial gate valves are widely utilized across various sectors, including water treatment, oil and gas, power generation, and chemical manufacturing. In water treatment facilities, for example, gate valves are crucial for regulating the flow of water during various treatment processes. Their ability to fully open or close makes them the ideal choice for shut-off applications, where interrupting the flow is necessary for maintenance or system adjustments.

In the oil and gas industry, gate valves are used extensively for on/off control, particularly in high-pressure applications. The reduced flow resistance when fully opened significantly increases efficiency, essential in operations where maintaining pressure is critical. Additionally, many industrial processes require gate valves to handle crude oil, natural gas, and other aggressive compounds, necessitating the use of durable materials that can withstand corrosion and high temperatures.

industrial gate valve

Power generation facilities utilize gate valves in both steam and water systems. These valves help control the flow of coolant or steam, playing a vital role in maintaining optimal operating conditions. By ensuring that these systems function seamlessly, gate valves contribute to the overall reliability and efficiency of power plants.

Advantages of Gate Valves

One of the primary advantages of industrial gate valves is their low friction loss. Unlike globe valves, which restrict flow even when open, gate valves provide a straight flow path that reduces energy loss. This characteristic makes them an excellent choice for applications where maintaining high flow rates is essential.

Additionally, gate valves offer a robust construction that can handle high pressures and temperatures, making them suitable for a wide range of industrial applications. Their simple design allows for easy maintenance, as they have fewer components compared to other types of valves. Fewer parts also mean a lower likelihood of failure, increasing the reliability of systems where they are installed.

Furthermore, gate valves are designed to be fully open or fully closed, providing operators with a clear indication of their status. This binary operation simplifies the control process, reducing the likelihood of misoperation and enhancing overall system safety.

Conclusion

In summary, industrial gate valves play a crucial role in the functioning of various industries. Their ability to provide efficient flow control, coupled with their durability and ease of maintenance, make them a preferred choice for many applications. As industries continue to evolve, the demand for reliable and efficient flow control solutions like gate valves will undoubtedly remain significant. Embracing advancements in materials and technology is key to enhancing the performance and longevity of these critical components in industrial operations.

Share