ਨਵੰ. . 09, 2024 07:04 Back to list

Ductile Iron Dismantling Joints for Efficient Pipeline Maintenance and Installation Solutions

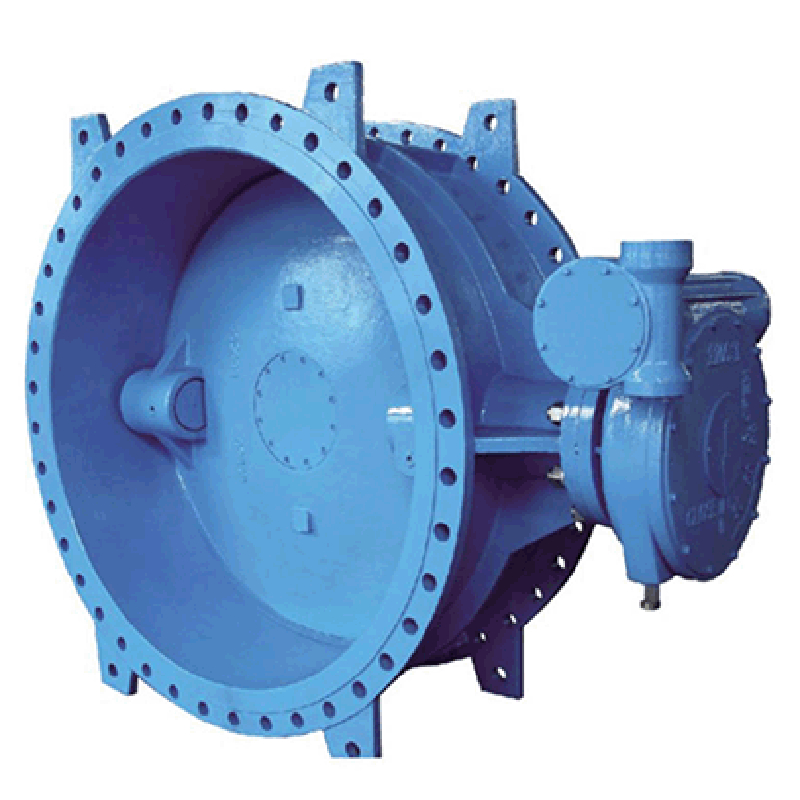

Understanding Ductile Iron Dismantling Joints A Key Component in Pipeline Systems

Ductile iron dismantling joints are critical components in modern pipeline systems. These joints offer a reliable solution for the assembly and maintenance of pipelines, particularly in water, wastewater, and industrial applications. By allowing for the disassembly of pipe sections without the need for cutting, ductile iron dismantling joints enhance efficiency, minimize downtime, and reduce maintenance costs.

What is a Ductile Iron Dismantling Joint?

A dismantling joint is a specialized fitting designed to connect two sections of pipe while allowing for disassembly at any time without disrupting the entire piping system. Typically made from ductile iron, these joints exhibit superior mechanical properties, including enhanced strength and ductility compared to traditional cast iron. Ductile iron can withstand higher pressures and offers better resistance to impact and fatigue, making it an ideal material for joints used in demanding environments.

Dismantling joints usually consist of several key components the body, end flanges, bolts, and gaskets. The body houses a flexible connection that allows for axial movement and disassembly. End flanges are used to connect the joint to adjacent pipes, while bolts secure the connection, ensuring it can handle the operational pressures within the system. Gaskets provide a watertight seal, preventing leaks and maintaining system integrity.

Applications of Ductile Iron Dismantling Joints

Ductile iron dismantling joints are commonly used in various industries, including municipal water supply, wastewater management, and industrial process applications. In municipal water systems, these joints facilitate quick access to valves, meters, and other pipeline components, allowing for timely repairs or replacements. In wastewater applications, dismantling joints enable easier maintenance of treatment facilities and pump stations, ensuring that systems operate efficiently and safely.

In industrial settings, ductile iron dismantling joints can often be found in chemical processing plants, power generation facilities, and food and beverage industries. Here, the ability to disassemble joints without significant delays is crucial for maintaining production timelines and ensuring safety protocols are met.

ductile iron dismantling joint

Advantages of Using Ductile Iron Dismantling Joints

1. Ease of Maintenance One of the most significant advantages of ductile iron dismantling joints is their ease of maintenance. The ability to quickly disassemble and reassemble sections of pipeline reduces downtime during repairs, thus enhancing system efficiency.

2. Cost-Effectiveness By minimizing the need for extensive modifications or replacements, these joints can lead to significant cost savings. The durability of ductile iron also means that the lifespan of the joints is longer, which translates into lower long-term maintenance costs.

3. Flexibility and Versatility Ductile iron dismantling joints can adapt to various system configurations, making them suitable for different types of piping layouts. Their ability to accommodate movement and adjustments further adds to their versatility.

4. Strong and Reliable Sealing The use of gaskets in conjunction with ductile iron provides reliable sealing, preventing leaks and ensuring the integrity of the piping system. This is particularly important in applications where even a small leak could lead to contamination or environmental issues.

5. Resistance to Corrosion Ductile iron joints are often coated with anti-corrosive materials to enhance their lifespan, particularly in aggressive environments. This resistance to corrosion ensures reliable operation over extended periods, reducing the need for frequent replacements.

Conclusion

In conclusion, ductile iron dismantling joints play an essential role in the operation and maintenance of pipeline systems across various industries. Their robust design, ease of use, and economic advantages make them indispensable in modern infrastructure. As the demand for reliable and efficient pipeline systems continues to grow, the importance of high-quality components like ductile iron dismantling joints will remain paramount. By understanding their functionality and benefits, engineers and project managers can make informed decisions to optimize pipeline performance and maintenance strategies.

Share