ਦਸੰ. . 05, 2024 15:30 Back to list

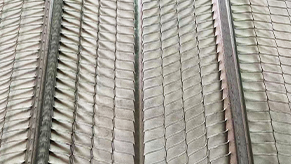

dismantling joint

Understanding Dismantling Joints Functionality and Applications

Dismantling joints, also known as dismantling flanges or dismantling joints, are essential components utilized in piping systems that require regular maintenance, inspection, or repair. These joints provide a flexible connection between two lengths of piping, allowing for easy disassembly without the need for cutting or damaging the pipe infrastructure. In this article, we will explore the design, functionality, benefits, and applications of dismantling joints.

What Are Dismantling Joints?

Dismantling joints are specialized mechanical fittings designed to enable the easy disassembly of pipes in a piping system. They typically consist of two flanges and a central body, which can either be made from ductile iron, carbon steel, or stainless steel, depending on the application and environmental requirements. The key feature of dismantling joints is their ability to allow a certain length of pipe to be removed from the joint without requiring considerable effort.

Design and Functionality

The design of a dismantling joint incorporates several critical components

1. Flanges Each side of the dismantling joint features flanges that connect to the adjacent pipes through bolts and nuts. These flanges ensure a secure connection while allowing for ease of disassembly.

2. Central Body The central section of the dismantling joint typically includes a sliding mechanism, which facilitates movement to accommodate changes in pipe alignment or length.

3. Gaskets Gaskets are used to create a watertight seal when the joint is assembled. They are typically made from rubber or other durable materials that can withstand pressure and temperature variances.

The functionality of the dismantling joint lies in its ability to shift and align the pipe system. When maintenance is required, operators can loosen the bolts, allowing the central body to slide, thereby providing access to the internal components of the pipeline. This design not only minimizes downtime during maintenance but also reduces the risk of damage to the existing piping.

Benefits of Dismantling Joints

Dismantling joints offer several advantages

dismantling joint

1. Ease of Access The primary benefit is the ability to access pipes quickly without the need for specialized tools or heavy machinery. This feature is invaluable in situations where time is of the essence, such as water treatment plants or industrial systems.

2. Cost Efficiency By facilitating swift maintenance or replacement of sections of pipes, dismantling joints help reduce labor costs and equipment rental fees. The efficiency gained can lead to significant savings over time.

3. Versatility Dismantling joints are suitable for a variety of applications, including water supply, sewage systems, HVAC installations, and industrial processes. Their ability to accommodate different pipe materials and sizes further enhances their versatility.

4. Reduced Risk of Damage Traditional methods of pipe disassembly can often lead to damage to the piping system, which may result in costly repairs. Dismantling joints minimize this risk by providing a safe, controlled environment for disassembly.

Applications of Dismantling Joints

Dismantling joints find application across various industries due to their unique features. Common areas of use include

- Water Treatment Facilities Facilities that require frequent inspection and maintenance of pipelines benefit significantly from dismantling joints, enabling quick modifications to the pipeline structure.

- Municipal Water Supply In municipal water systems, dismantling joints facilitate easy access for repairs and ensure the system's integrity is maintained without extensive downtime.

- Industrial Settings Many industrial processes involve the transport of fluids or gases under various conditions. Dismantling joints make it easier to manage and maintain complex piping networks found in manufacturing and processing plants.

- HVAC Systems In heating, ventilation, and air conditioning systems, dismantling joints allow for efficient maintenance of air ducts and piping, ensuring optimal operation.

Conclusion

Dismantling joints represent a crucial innovation in the field of piping systems, combining functionality and practicality to enhance maintenance efforts. Their ability to facilitate quick access to pipelines while minimizing the risk of damage offers a cost-effective and efficient solution for various applications. As industries continue to prioritize sustainability and operational efficiency, dismantling joints will remain a valuable component in ensuring the reliability and longevity of piping systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025