ਦਸੰ. . 03, 2024 18:20 Back to list

Durable Cast Iron Y Strainer for Efficient Filtration and Pipeline Protection

Understanding Cast Iron Y Strainers Applications and Benefits

When it comes to industrial fluid management, certain components play a critical role in ensuring efficiency and reliability. One such component is the cast iron Y strainer, a vital piece of equipment used widely in various sectors, including water treatment, oil and gas, and chemical processing. This article delves into the design, functionality, advantages, and applications of cast iron Y strainers.

What is a Cast Iron Y Strainer?

A Y strainer is a type of filtering device that effectively removes debris and particulates from fluids in pipelines. The design resembles the letter Y, which allows it to fit conveniently in piping systems. Cast iron, as the material of choice for many Y strainers, provides resilience and durability due to its strength and resistance to corrosion, making it ideal for handling harsh fluids and environments.

The Y strainer is installed in a system's pipeline to prevent contaminants from clogging valves, pumps, and other components, thereby ensuring smooth operation. The debris collected inside the strainer can be periodically removed through a process known as blowing down, maintaining the flow without extensive downtime.

Design and Features

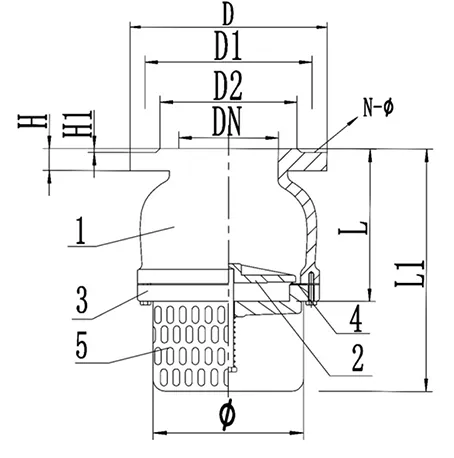

The construction of a cast iron Y strainer typically includes a straining element, a body, and an access port. The straining element may consist of a mesh filter or perforated screen designed to capture different sizes of particles. The choice of mesh depends on the specific application and the type of debris expected in the fluid.

Moreover, the design of the Y strainer often allows for easy maintenance. The access port provides straightforward access for cleaning and inspection, ensuring the device remains efficient. Some models are equipped with a blow-off valve or a manual drain to facilitate quicker maintenance without having to remove the strainer from the pipeline.

Advantages of Cast Iron Y Strainers

1. Durability Cast iron is renowned for its long-lasting properties. It can withstand high pressures and temperatures, making it suitable for various demanding environments.

2. Corrosion Resistance Among the many materials available, cast iron provides considerable resistance to corroding agents, allowing Y strainers to perform effectively in corrosive fluids.

cast iron y strainer

4. Versatile Applications Cast iron Y strainers can be utilized in numerous sectors, including water treatment, petroleum production, and cooling systems, because of their adaptability to different environmental conditions.

5. Efficient Filtration With the capability to capture varying particle sizes, Y strainers ensure that systems operate efficiently without unplanned disruptions caused by debris buildup.

Applications of Cast Iron Y Strainers

1. Municipal Water Systems In water treatment facilities, cast iron Y strainers are essential for protecting pumps and other critical components from particulates, thus ensuring clean water delivery to communities.

2. Oil and Gas Industries These strainers are used in pipelines to filter out sand, dirt, and other unwanted materials that can damage equipment or reduce efficiency in processing raw materials.

3. Chemical Processing In chemical plants, cast iron Y strainers help maintain the quality of the produced chemicals by preventing contamination from particulates that may be present in the input materials.

4. HVAC Systems In heating, ventilation, and air conditioning systems, Y strainers are employed to protect pumps and valves from damage caused by debris in the water or coolant.

5. Irrigation Systems Agriculture also benefits from Y strainers, as they help filter out debris from water supply lines, thus preserving the efficiency and longevity of irrigation equipment.

Conclusion

Cast iron Y strainers are indispensable tools in various industrial processes. Their durability, resistance to corrosion, and ability to maintain system efficiency set them apart in fluid management applications. As industries continue to strive for higher efficiency and reliability, the use of cast iron Y strainers will undoubtedly remain a sensible choice for engineers and maintenance professionals alike. Whether it’s in water treatment plants or chemical processing facilities, investing in high-quality straining solutions translates to improved operational performance and reduced maintenance headaches.

Share