ਦਸੰ. . 21, 2024 12:07 Back to list

bidirectional knife gate valve

Understanding Bidirectional Knife Gate Valves

Bidirectional knife gate valves are specialized valves that play a crucial role in various industrial applications. These uniquely designed valves are particularly well-suited for controlling the flow of slurries, liquids, and gases in different piping systems. This article aims to delve into the functionality, advantages, and applications of bidirectional knife gate valves, providing a comprehensive understanding of their significance in modern engineering.

What Are Bidirectional Knife Gate Valves?

A bidirectional knife gate valve is a type of isolation valve that features a sharp blade (or knife) designed to cut through tough materials, including slurries and solids. Unlike conventional gate valves, which primarily handle clean fluids, knife gate valves are engineered to manage systems where the medium is more viscous or contains particulates. The term bidirectional indicates the valve's ability to control fluid flow in both directions, offering versatility in piping layouts.

Construction and Design

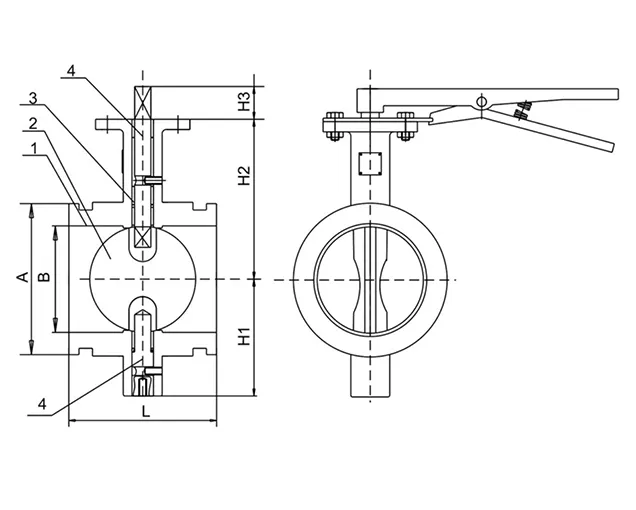

The design of a bidirectional knife gate valve is robust and straightforward, composed of a body, blade, seat, and actuator. The blade is made of durable materials such as stainless steel or carbon steel, allowing it to withstand abrasive and corrosive environments. The seat, typically made of elastomeric materials, provides a tight seal when the valve is closed, preventing leakage.

These valves are often fabricated with a rectangular or square body, facilitating their installation in tight spaces and ensuring that they can handle the flow of media effectively. The actuators used can be manual gears, pneumatic actuators, or electric motors, allowing for remote operation and automation in complex systems.

Advantages of Bidirectional Knife Gate Valves

1. Reduced Leakage The design of the knife blade and seat ensures minimal leakage, making it ideal for applications requiring tight sealing, such as wastewater treatment and pulp and paper industries.

2. Ease of Cleaning The simpler construction allows for easy maintenance and cleaning. This is particularly advantageous in applications where clogging might occur.

3. Operational Versatility Their bidirectional capability means they can be used in various configurations, enhancing system flexibility. This is especially useful in large facilities with complex piping networks.

bidirectional knife gate valve

4. High Flow Capacity Because of their unique design, knives gate valves can handle high flow rates, making them suitable for applications involving large volumes of fluids or slurries.

5. Durability Built to withstand harsh operational environments, bidirectional knife gate valves offer longevity, reducing the need for frequent replacements.

Applications

Bidirectional knife gate valves find applications across various industries, including

- Wastewater Treatment These valves are essential in controlling the flow of sludge and other solids in wastewater treatment plants. They help mitigate blockages and manage the flow of effluent through different processes.

- Pulp and Paper Industry In the production of paper, handling slurry and other fibrous materials is critical. Knife gate valves are utilized in various stages of pulp processing, ensuring efficient and reliable operation.

- Mining and Minerals Processing The handling of slurries in mining operations often requires robust valves that can cut through solid materials. Bidirectional knife gate valves are employed in mineral processing to control the flow of ore and tailings.

- Chemical Processing Many chemical processes involve viscous materials and slurries. These valves provide the necessary isolation and control required in various chemical applications.

Conclusion

Bidirectional knife gate valves are invaluable components in many industrial systems, providing reliable flow control and isolation for challenging materials. Their unique design and versatility cater to a wide range of applications, highlighting their importance in sectors like wastewater treatment, pulp and paper, mining, and chemical processing. As industries continue to innovate and seek efficient solutions for managing fluid flow, the role of bidirectional knife gate valves will undoubtedly grow, making them a fundamental choice for engineers and project managers alike. Understanding their construction, advantages, and applications ensures that industries can leverage this essential technology effectively, optimizing their operational efficiency while maintaining safety and reliability.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025