ਨਵੰ. . 05, 2024 20:38 Back to list

ball valve with y strainer

Understanding the Ball Valve with Y Strainer A Comprehensive Overview

In the realm of fluid control, the combination of a ball valve with a Y strainer represents a powerful solution for industries that require efficient flow management alongside effective filtration. Both components serve crucial roles in maintaining system integrity and operational efficiency.

What is a Ball Valve?

A ball valve is a type of quarter-turn valve that utilizes a hollow, perforated, and pivoting ball to control the flow of liquid or gas. Its design allows for quick opening and closing, ensuring efficient flow regulation. When the ball’s hole is aligned with the flow, the valve is open; when it’s turned perpendicular, the flow is blocked. This straightforward mechanism ensures minimal pressure drop and provides a reliable seal when closed, making ball valves ideal for various applications, from residential plumbing to industrial processes.

The Role of a Y Strainer

A Y strainer, on the other hand, is a filtration device that serves to remove unwanted particles from a fluid flow, thereby protecting downstream equipment like pumps, compressors, and valves from damage caused by debris. The 'Y' shape of the strainer allows it to be installed in a pipeline without taking up excessive space. The mesh filtration element can be easily removed and cleaned, catering to maintenance needs without the hassle of complete disassembly.

The Synergy of Ball Valves and Y Strainers

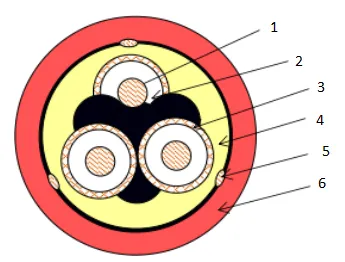

ball valve with y strainer

Integrating a ball valve with a Y strainer presents several advantages in fluid handling systems. The combination allows for both flow control and filtration in a compact design, simplifying system design and reducing the number of necessary components. This synergy results in lower installation costs and improved reliability, as engineers can avoid issues related to improper system assembly.

One of the most significant benefits of this combination is the enhanced safety and longevity it provides for the entire piping system. The Y strainer captures unwanted particles, preventing blockages and wear in downstream valves and equipment. Consequently, the ball valve can operate more efficiently and with less risk of failure. This is particularly crucial in industries such as water treatment, chemical processing, and oil and gas, where system reliability is paramount.

Considerations for Installation and Maintenance

When integrating ball valves with Y strainers, it’s essential to ensure proper installation. The direction of flow must align with the strainer’s orientation, and the ball valve should be positioned appropriately for easy access during maintenance. Regular inspection and cleaning of the Y strainer mesh are critical; neglecting to do so can lead to reduced flow rates and increased pressure, ultimately affecting operational efficiency.

Furthermore, choosing the correct materials for both the valve and strainer based on the specific fluid being transported is crucial. Materials must withstand the corrosive or abrasive properties of the media to ensure longevity and performance.

Conclusion

The ball valve with Y strainer combination is a testament to effective fluid management solutions. By offering precise flow control and robust filtration, this duo enhances the efficiency, safety, and reliability of fluid systems across various industries. Proper understanding and maintenance of these components can lead to significant operational advantages, making them indispensable in modern engineering practices. As industries continue to evolve, the importance of such integrations will undoubtedly grow, accentuating the need for intelligent fluid management systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025