ਨਵੰ. . 10, 2024 00:02 Back to list

Air Pressure Control Valve for Enhanced System Performance

The Importance of Air Valves in Modern Systems

Air valves are essential components in various systems, playing a crucial role in maintaining efficiency and functionality. Their primary purpose is to control the flow of air in different applications, including HVAC systems, pneumatic tools, and industrial machinery. Understanding their function and importance can help in optimizing performance and prolonging equipment life.

Understanding Air Valves

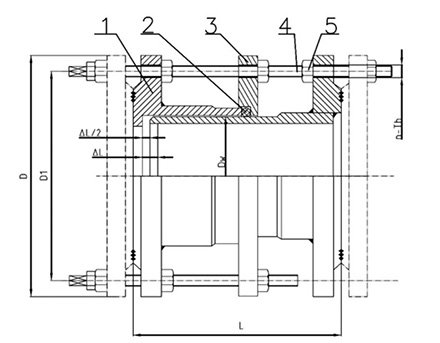

An air valve is a device utilized to manage the flow of air, allowing for controlled entry and exit of air within a system. These valves can be categorized into several types, including manual valves, solenoid valves, and pressure relief valves, each designed to address specific requirements. Manual valves require human intervention to operate, while solenoid valves use electrical signals to automate air flow control. Pressure relief valves are crucial in protecting equipment from excessive pressure by releasing air when it exceeds a designated level.

Applications of Air Valves

Air valves are commonly found in residential and commercial heating, ventilation, and air conditioning (HVAC) systems. In these setups, they help regulate airflow, ensuring that spaces remain comfortable and efficiently heated or cooled. This is crucial not only for occupant comfort but also for energy efficiency; poorly managed airflow can lead to energy waste and higher utility costs.

In the industrial sector, air valves are pivotal in pneumatic systems, which rely on compressed air to power tools and machinery. They ensure that the right amount of air is delivered to the tools, enhancing performance and preventing potential failures due to insufficient airflow. Proper air valve management in these settings can lead to increased productivity, as operations become smoother and more reliable.

The Role of Air Valves in Energy Efficiency

air valve

One of the most significant advantages of integrating air valves into a system is the enhancement of energy efficiency. By accurately regulating airflow, these valves minimize energy consumption, contributing to sustainable practices. For instance, in HVAC systems, using air valves to balance airflow can significantly reduce the load on heating and cooling units, leading to lower energy bills and reduced carbon footprints.

Moreover, advanced air valves equipped with smart technology can further optimize air distribution. These smart valves can monitor environmental conditions and automatically adjust their operation, ensuring that the system only uses the necessary energy for heating or cooling. This intelligent management not only enhances comfort but also promotes energy conservation.

Maintenance and Considerations

While air valves are durable components, they require regular maintenance to function efficiently. Over time, dust and debris can accumulate, obstructing airflow and leading to inefficiencies or failures. Regular inspections and cleanings can prolong the life of air valves and ensure that systems operate at peak performance.

When selecting air valves, it is essential to consider factors such as the system’s pressure requirements, the specific application, and the compatibility of materials. Investing in high-quality valves suited for the intended purpose can yield significant long-term benefits and savings.

Conclusion

In conclusion, air valves are paramount in both residential and industrial applications, controlling airflow and enhancing energy efficiency. Their role in maintaining the balance within air systems cannot be underestimated. By understanding and properly maintaining these devices, users can ensure optimal performance, sustainability, and comfort in various environments. As technology continues to advance, the future of air valves looks promising, with smart innovations paving the way for even greater efficiencies and capabilities. Whether in homes or factories, paying attention to air valves is essential for maximizing performance and achieving environmental goals.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025