ਨਵੰ. . 23, 2024 18:11 Back to list

4 Inch Check Valve Selection and Installation Guide for Optimal Performance

Understanding the 4-Inch Check Valve A Crucial Component in Fluid Systems

Check valves are essential components in fluid handling systems, ensuring that liquids and gases flow in one direction while preventing backflow. Among the various sizes and types available, the 4-inch check valve is a popular choice due to its versatility and efficiency in a range of applications. This article aims to explore the features, applications, and benefits of the 4-inch check valve, shedding light on its significance in modern engineering and fluid dynamics.

What is a Check Valve?

A check valve, sometimes referred to as a non-return valve, is a mechanical device that allows fluid (liquid or gas) to flow through it in one direction. The primary function of a check valve is to prevent backflow, which can lead to system inefficiencies, equipment damage, or contamination. Check valves operate automatically, relying on the pressure differential between the upstream and downstream sides to open or close.

Features of the 4-Inch Check Valve

The 4-inch check valve is designed to handle a significant flow rate, making it suitable for various industrial applications. Common features include

1. Size and Port Configuration With a nominal diameter of 4 inches, these valves can accommodate substantial volumes of fluid. They often come with standard flange connections or threaded ends for easy integration into existing piping systems.

2. Materials Check valves can be constructed from various materials, depending on the application. Common materials include stainless steel, brass, PVC, and cast iron. The choice of material influences the valve's durability, resistance to corrosion, and overall performance.

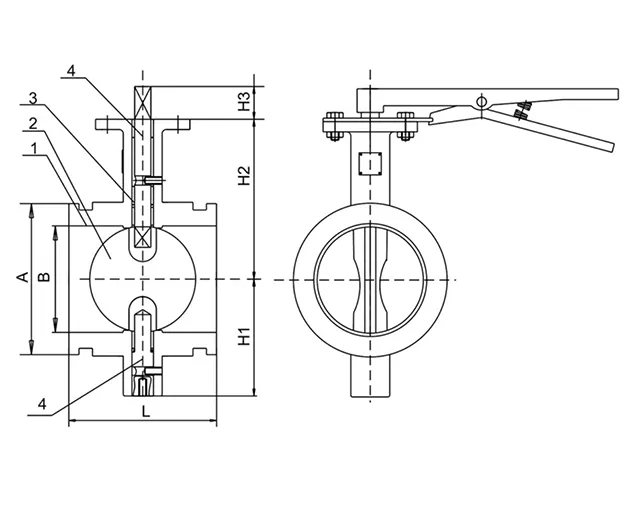

3. Design Variations There are different designs of check valves, including swing, lift, and diaphragm types. The swing check valve, commonly used for its robust performance, features a disc that swings open and closed based on flow direction, while lift check valves rely on a disc that lifts off its seat.

4. Pressure Ratings 4-inch check valves are available in various pressure ratings to suit different operational requirements. Common ratings range from 150 psi to 300 psi, though specialized high-pressure variants are also available.

Applications

The 4-inch check valve finds applications across a wide spectrum of industries, including but not limited to

- Water and Wastewater Treatment In municipal water systems, these valves help prevent backflow from drainage systems, ensuring clean water supply.

4 inch check valve

- Pumping Stations They are vital in preventing backflow in pumping stations, safeguarding pumps from damage and maintaining efficiency.

- HVAC Systems In heating and cooling systems, check valves help maintain proper flow direction, preventing reverse flow that could disrupt system performance.

- Oil and Gas In the oil and gas industry, check valves are crucial in preventing backflow during the extraction and transport of hydrocarbons, ensuring safety and efficiency.

- Food and Beverage Check valves are widely used in processing plants to guard against contamination and maintain product quality

.Benefits of Using a 4-Inch Check Valve

1. Backflow Prevention The primary benefit is their ability to prevent backflow, safeguarding both equipment and processes.

2. Simple Operation Check valves operate automatically based on pressure, which reduces the need for manual intervention and enhances system efficiency.

3. Durable and Reliable Constructed from robust materials, 4-inch check valves are designed for longevity, even in demanding environments.

4. Versatility Their applicability across various industries makes them a practical choice for engineers and system designers.

5. Cost-Effective By preventing backflow and potential damage, these valves can save organizations money in repair and maintenance costs.

Conclusion

The 4-inch check valve is an indispensable component in fluid dynamics and system design. Its ability to prevent backflow, coupled with its durability and versatility, makes it a valuable asset in industries ranging from water treatment to oil and gas. Understanding the importance and functionality of check valves ensures that engineers and operators can design efficient and reliable fluid handling systems for a diverse array of applications. Whether you are involved in the design, installation, or maintenance of such systems, the 4-inch check valve is a component worth considering for optimal performance and safety.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025