Nov . 15, 2024 23:58 Back to list

pneumatic butterfly valve

Understanding Pneumatic Butterfly Valves A Comprehensive Overview

Pneumatic butterfly valves are essential components in various industrial and commercial applications, known for their efficiency and ease of operation. These valves are designed to regulate flow in a pipeline by using a circular disc, which can be rotated to either allow or restrict fluid flow. The operation is controlled by a pneumatic actuator, making it an optimal choice for automation in different industries.

The Design of Pneumatic Butterfly Valves

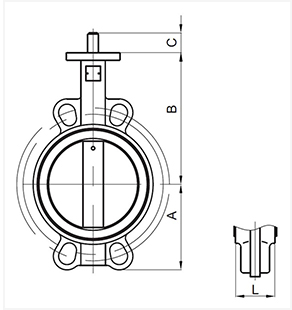

The basic design of a pneumatic butterfly valve includes three primary parts the body, the disc (or blade), and the actuator. The valve body is usually made from materials like cast iron, stainless steel, or plastic, depending on the application requirements. The disc is mounted on a shaft in the middle of the valve body, allowing it to rotate 90 degrees. This rotation either opens or closes the flow path.

The actuator, which is powered by compressed air, is critical for the functioning of the pneumatic butterfly valve. When air pressure is applied, the actuator moves the disc to the desired position—fully open, fully closed, or anywhere in between. This setup offers fine control over the flow rate, making it suitable for various applications, including water treatment, chemical processing, and HVAC systems.

Advantages of Pneumatic Butterfly Valves

One of the primary advantages of pneumatic butterfly valves is their quick operation. Unlike other types of valves that may require more extensive mechanisms and longer response times, butterfly valves can be opened or closed rapidly, making them ideal for applications where speed is crucial.

pneumatic butterfly valve

Additionally, these valves are lightweight compared to other valve types, such as gate or globe valves. This lightweight nature not only simplifies installation but also reduces the overall structural load on pipelines and supporting frameworks. The design of pneumatic butterfly valves also allows for less space to be used, making them suitable for installations where space is at a premium.

Another key benefit is their lower pressure drop compared to other valve types. This characteristic is particularly valuable in processes where maintaining pressure is vital, as it minimizes energy loss and optimizes system efficiency. Furthermore, pneumatic butterfly valves can handle a wide range of temperatures and pressures, making them versatile for different industrial applications.

Applications of Pneumatic Butterfly Valves

Pneumatic butterfly valves are widely used in various sectors. In the water treatment industry, they play a crucial role in controlling the flow of water through different stages of treatment processes. In chemical manufacturing, these valves regulate the flow of chemicals with precision, ensuring safety and efficiency.

In HVAC systems, pneumatic butterfly valves are employed to control airflow, ensuring optimal climate control in buildings and industrial facilities. Their ability to handle fluids, slurries, and gases makes them suitable for a diverse array of industries, including food and beverage, pharmaceuticals, and oil and gas.

Conclusion

In summary, pneumatic butterfly valves are vital components in modern industrial applications. Their design, characterized by efficiency, quick operation, and a lightweight structure, allows for effective flow control in various settings. As industries continue to evolve and demand for automation increases, the importance of pneumatic butterfly valves will only grow, reaffirming their status as indispensable tools in fluid management. Choosing the right valve type can significantly impact operational efficiency and safety, making a thorough understanding of pneumatic butterfly valves essential for professionals across multiple sectors.

Share