Dec . 05, 2024 22:25 Back to list

flap check valve

Understanding Flap Check Valves Function, Types, and Applications

Flap check valves are essential components in various fluid handling systems, designed primarily to prevent backflow and ensure the unidirectional flow of liquids and gases. These valves are commonly used in industries such as water treatment, oil and gas, and HVAC systems, where maintaining the integrity of flow direction is critical. In this article, we will explore the function, types, and applications of flap check valves.

Function of Flap Check Valves

A flap check valve operates on a simple principle it consists of a hinged flap or disc that opens in the direction of flow and closes when the flow reverses. This mechanism prevents backflow, which can cause damage to pumps, piping systems, and other equipment. When fluid flows in the intended direction, the pressure lifts the flap, allowing flow through the valve. However, if the flow attempts to reverse, the flap falls back into a closed position due to gravity or spring tension, sealing the valve and stopping the backflow.

This design is beneficial in preventing issues such as water hammer—a pressure surge caused by sudden changes in flow—occurred when a pump shuts off or a valve closes quickly. The flap's swift closure helps mitigate these issues, safeguarding the entire system.

Types of Flap Check Valves

Flap check valves are available in several designs, each suited for different applications and operating conditions

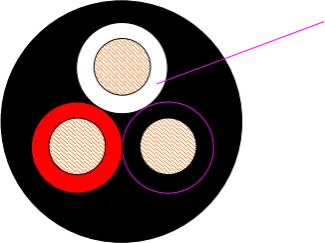

1. Swing Check Valve This is the most common type and features a disc that swings on a hinge. It is primarily used in horizontal pipelines and is ideal for low-pressure systems.

flap check valve

2. Lift Check Valve Unlike the swing check, the lift check valve has a disc that moves vertically. These valves are generally used in vertical pipelines and can handle higher pressures, making them suitable for more demanding applications.

3. Dual Plate Check Valve This design incorporates two plates that allow for a quick closure and minimal pressure drop. It is often used in larger pipelines and is valued for its lightweight and compact design.

4. Ball Check Valve This valve features a ball that rests in a seat. When fluid flows in the correct direction, the ball moves away, allowing flow. If the flow reverses, the ball is pushed back into the seat, preventing backflow. This type is common in smaller applications.

Applications of Flap Check Valves

Flap check valves are used in a wide range of applications. In the water and wastewater industry, they are utilized to prevent backflow in pumping stations and treatment facilities, ensuring that clean water is not contaminated by backflow from sewage systems. In the oil and gas sector, flap check valves play a crucial role in pipeline systems, safeguarding against backflow that could lead to system failures or hazards.

Additionally, these valves are commonly found in HVAC systems to maintain airflow direction, ensuring that conditioned air flows appropriately and does not flow back into the duct system. Their reliable performance makes them indispensable in maintaining system efficiency and safety across various applications.

Conclusion

Flap check valves are vital components that ensure efficient fluid management in numerous industries. Their simple yet effective design allows them to prevent backflow, protecting systems from pressure surges and potential damage. With various types available to suit different applications, understanding the specific requirements of your system is essential in selecting the right flap check valve for optimal performance.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025