Dec . 07, 2024 05:57 Back to list

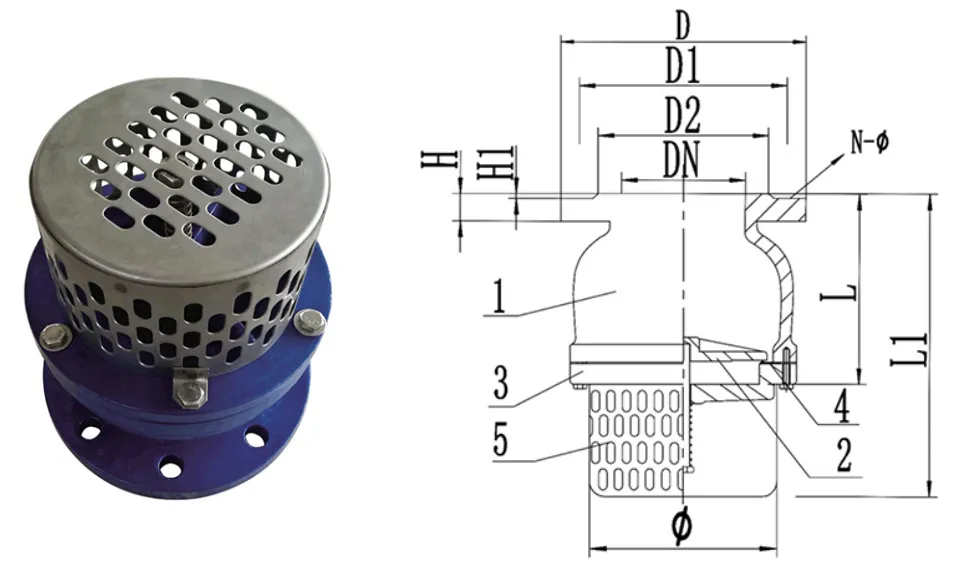

ductile iron ball check valve

Understanding Ductile Iron Ball Check Valves Key Features and Benefits

Ductile iron ball check valves are essential components in various fluid transfer and management systems. They are manufactured from ductile iron, a material known for its excellent mechanical properties, including strength, toughness, and ductility. This article aims to explore the importance of ductile iron ball check valves, their features, applications, and benefits.

What is a Ball Check Valve?

A ball check valve is a type of valve that allows fluid to flow in one direction while preventing backflow. It typically consists of a spherical ball that sits inside a flanged or threaded valve body, with the fluid flow direction influencing the ball’s position. When fluid enters the valve from the inlet side, the pressure displaces the ball, allowing the fluid to pass. In the event of reverse flow, the ball is pushed against the valve seat, effectively sealing the flow path and preventing backflow.

Ductile Iron as a Material

Ductile iron, also known as spheroidal graphite iron, is created by adding small amounts of magnesium to cast iron. This process results in a material that exhibits enhanced strength and flexibility compared to traditional cast iron. Ductile iron has several advantages, making it suitable for constructing ball check valves, including

1. High Tensile Strength Ductile iron boasts significantly greater tensile strength than cast iron, enabling the valve to withstand higher pressures and harsher working conditions.

2. Resistance to Corrosion The treatment process of ductile iron improves its resistance to corrosion, extending the lifespan of valves used in various applications, particularly in water and wastewater systems.

3. Durability The toughness of ductile iron means that valves can successfully endure the mechanical stresses and impacts they may face in various operating environments.

4. Cost-Effective While ductile iron may come at a slightly higher initial cost than standard cast iron, its durability and longevity often make it a more economical choice over time.

Key Features of Ductile Iron Ball Check Valves

ductile iron ball check valve

2. Versatile Installation Ductile iron ball check valves can be installed in various orientations (horizontal, vertical, or angled), making them adaptable to numerous piping configurations.

3. Maintenance-Free Design These valves typically require minimal maintenance, thanks to their robust construction and reliable sealing capabilities, reducing the need for regular checks and repairs.

4. Wide Temperature Range Ductile iron can endure a wide range of temperatures, making these ball check valves suitable for various environments, from cold water systems to hot industrial applications.

Applications of Ductile Iron Ball Check Valves

Ductile iron ball check valves find utility in various industries due to their versatility and reliability. Common applications include

- Water Supply and Distribution Used in municipal water systems to prevent backflow and ensure the safe distribution of potable water.

- Wastewater Management Essential in sewage and wastewater treatment facilities, where preventing backflow is crucial for environmental protection.

- Industrial Processes Incorporated in a range of industrial applications to manage fluid transport, including chemical processing, power generation, and more.

- Fire Protection Systems Adopted in fire protection systems to maintain water flow direction and control in emergency situations.

Conclusion

Ductile iron ball check valves are a vital component in fluid management systems across various industries. Their robust construction, high strength, and durability make them a preferred choice for applications that require reliable performance and long service life. By understanding the features and benefits of these valves, engineers, and procurement professionals can make informed decisions when designing systems that prioritize efficiency, safety, and sustainability. As industries continue to evolve, the role of ductile iron ball check valves will remain significant in the pursuit of effective fluid management solutions.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025