Dec . 04, 2024 15:58 Back to list

Rubber Joint for Double Sphere Union Type Applications and Benefits

Understanding the Double Sphere Union Type Rubber Joint

Rubber joints play a crucial role in modern engineering and construction, providing flexibility and resilience in various applications. Among the different types of rubber joints available, the double sphere union type rubber joint stands out due to its unique design and versatile functionality.

What is a Double Sphere Union Type Rubber Joint?

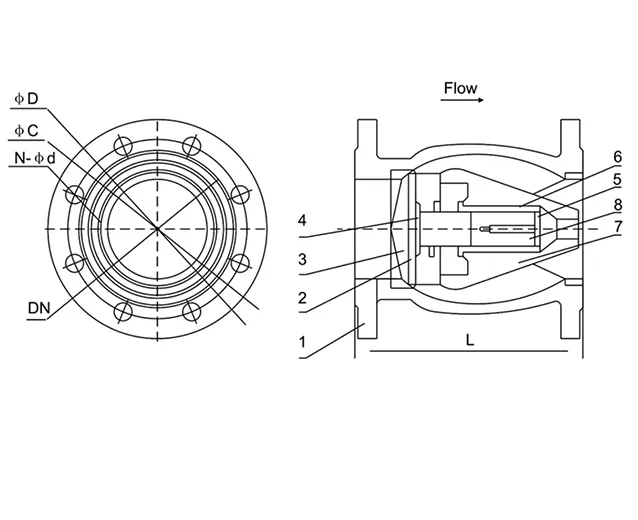

A double sphere union type rubber joint consists of two spherical rubber ends connected by a central pipe section. This configuration allows for angular movement, axial compression, and lateral displacement. Specifically designed to absorb vibrations and reduce stress caused by movement or misalignment in piping systems, this type of joint is essential for maintaining the integrity of pipelines carrying liquids or gases.

Key Features and Benefits

1. Flexibility The double sphere design allows for multidirectional movement. This means that it can accommodate changes in alignment due to thermal expansion, settling of structures, or other environmental factors. Flexibility is critical in preventing the transmission of excessive forces to connected equipment, which can lead to premature failure.

2. Vibration Absorption These joints are particularly effective in dampening vibrations generated by pumps, compressors, and other machinery. By absorbing these vibrations, they help to protect the integrity of the connected systems and reduce noise pollution.

3. Leak Prevention The rubber material used in the joints creates a tight seal between the fittings, minimizing the risk of leakage. This is vital for systems that transport hazardous materials, as even a small leak can have significant consequences.

4. Corrosion Resistance Unlike metal joints, rubber joints do not corrode when exposed to water or other potentially harmful substances. This longevity ensures a sustainable and cost-effective solution for piping systems.

double sphere union type rubber joint

5. Ease of Installation The lightweight nature and compact design of double sphere rubber joints facilitate easy installation, even in confined spaces. This can significantly reduce labor costs and installation time.

Applications

Double sphere union type rubber joints are used in a wide range of applications across various industries, including

- Water Treatment Plants They are vital for accommodating movements in pipelines transporting water and treating effluents. - HVAC Systems These joints are integral in heating, ventilation, and air conditioning systems, where movement and vibrations can be prevalent. - Industrial Processes In factories and plants, these joints help manage fluid and gas transportation while minimizing mechanical stress. - Marine Applications They are used in shipbuilding and repair, ensuring flexibility and reliability in critical systems.

Maintenance Considerations

While double sphere rubber joints are designed for durability, regular maintenance is essential to maximize their lifespan and effectiveness. Users should routinely inspect the joints for any signs of wear, such as cracking or degradation of the rubber material. It is also advisable to check for proper alignment and to ensure that they are not subjected to excessive loads or pressures beyond their rated capacity.

If replacements are necessary, it is crucial to select joints that match the specific requirements of the application, including size, pressure rating, and material compatibility. Working with experienced suppliers can help ensure that the right products are used for optimal performance.

Conclusion

The double sphere union type rubber joint is an indispensable component in modern piping systems. Its unique design offers unmatched flexibility, vibration absorption, and corrosion resistance, making it suitable for a myriad of applications. By reducing the risk of leaks and mechanical failure, these joints contribute to the efficiency and safety of various industrial processes. Proper installation and routine maintenance will ensure that they continue to offer reliable performance for years to come, reaffirming their importance in engineering and construction.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025