Nov . 15, 2024 04:51 Back to list

dismantling joint

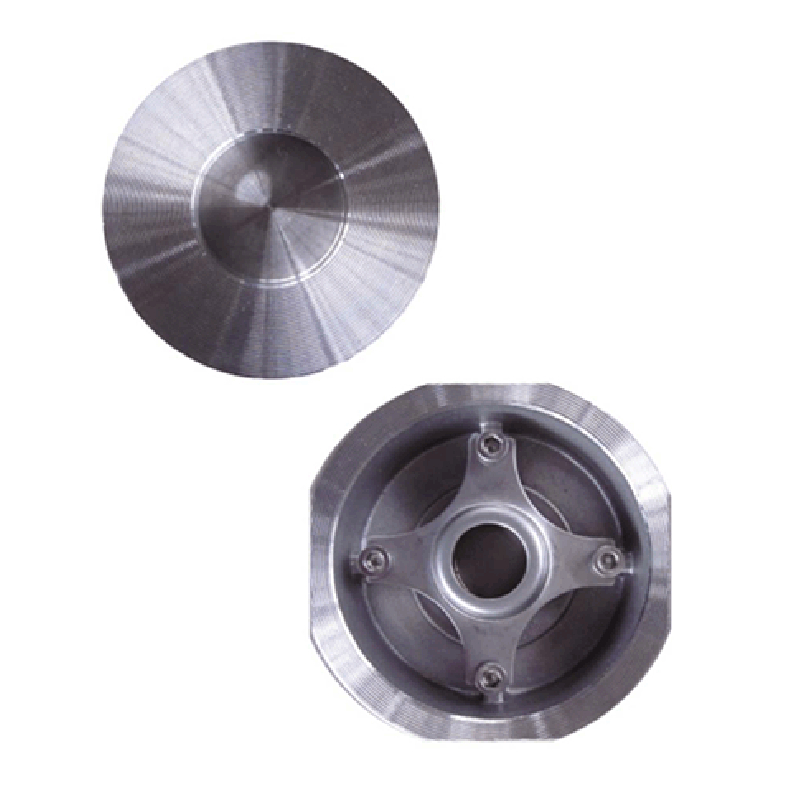

Dismantling Joints An Overview

Dismantling joints play a crucial role in the world of pipe systems and industrial installations. They are essential components designed to facilitate the separation of pipe sections, allowing for maintenance, repair, or replacement, without disturbing the entire system. This feature is especially important in industries that rely on extensive piping networks, such as water treatment, oil and gas, and chemical processing.

A dismantling joint typically consists of flanged connections that allow for the easy disassembly of joined pipes. This design minimizes downtime during maintenance by enabling workers to disconnect and relocate sections of the system swiftly. The joint usually contains gasket materials to ensure a tight seal, preventing leaks when reassembled. The versatility of dismantling joints allows them to accommodate varying pressures and temperatures, making them suitable for a wide range of applications.

One of the key benefits of using dismantling joints is their ability to provide flexibility in piping systems. They are designed to absorb thermal expansion, vibrations, and movements resulting from ground shifts or changes in system pressure. This flexibility helps maintain the integrity of the piping system over time, reducing the likelihood of leaks or failures that can occur in rigid setups.

dismantling joint

In addition to their functional advantages, dismantling joints also contribute to the overall safety of the system

. By allowing for quick access to piping sections, they enable operators to perform inspections and repairs more efficiently. This can be particularly vital in industries dealing with hazardous materials, where the safety of personnel and the environment is a top priority.When selecting dismantling joints, several factors must be considered, including the type of fluid being transported, the pressure and temperature conditions, and the material compatibility. Common materials for dismantling joints include stainless steel, carbon steel, and various alloys, each chosen for their specific properties and resistance to corrosion.

Installation of dismantling joints requires careful planning and adherence to industry standards. It is essential that the joints are installed correctly to ensure optimal performance and longevity. Regular inspections should also be conducted to identify any signs of wear or damage, allowing for timely maintenance that can prevent costly system failures.

In summary, dismantling joints are vital components in modern piping systems, offering ease of maintenance and increased safety. Their ability to facilitate quick access to piping sections while accommodating system flexibility makes them invaluable in various industrial applications. As technology and materials continue to evolve, the design and efficiency of dismantling joints will likely improve, further enhancing their role in ensuring reliable and safe piping systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025