Dec . 03, 2024 18:34 Back to list

cast steel check valve

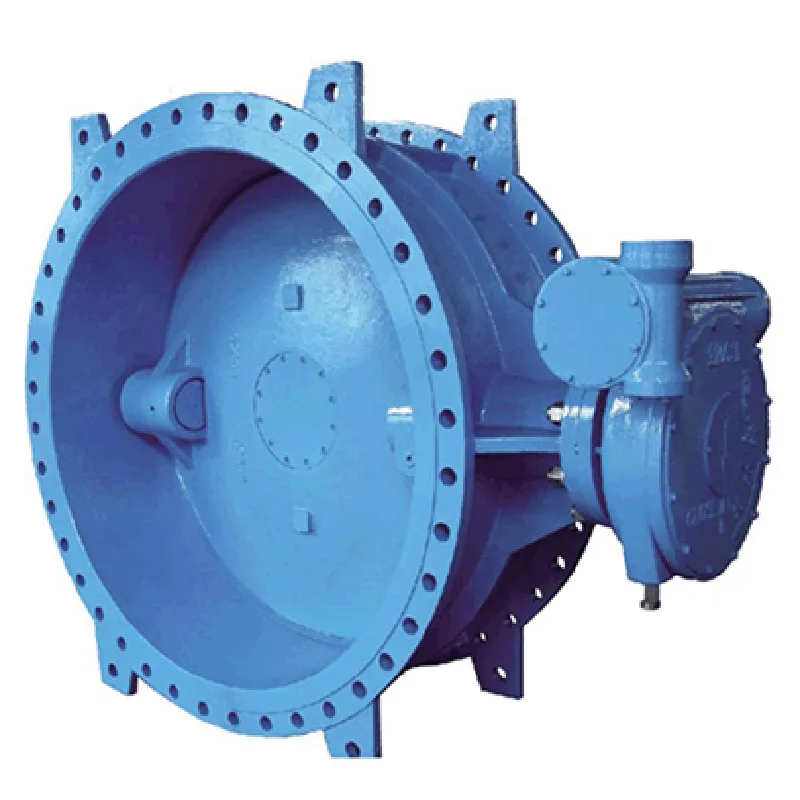

Understanding Cast Steel Check Valves An Essential Component in Fluid Systems

Cast steel check valves play a vital role in various fluid systems, ensuring that flow proceeds in one direction while preventing backflow. This essential piece of equipment is primarily used in pipelines and different industrial applications, contributing to the safety and efficiency of fluid transport. In this article, we will delve into the design, functionality, advantages, and applications of cast steel check valves.

What is a Cast Steel Check Valve?

A cast steel check valve is a type of valve that automatically prevents the reversal of flow within a piping system. It is made from cast steel, which provides superior strength and durability. These valves utilize gravity and the pressure of the fluid itself to open and close, making them a dependable choice for applications that require minimal human intervention. The design typically incorporates a disk or a ball that moves away from the seat when fluid flows in the intended direction and returns to the seat to block reverse flow when the pressure drops.

Design and Functionality

The construction of cast steel check valves allows for robust performance under high pressure and temperature conditions. Commonly used designs include swing check valves and lift check valves.

1. Swing Check Valves This design includes a swinging mechanism that operates like a door. When fluid flows through the valve in the intended direction, the disk swings open. If there is any backflow, gravity drives the disk closed against the seat, effectively preventing backflow.

2. Lift Check Valves These valves feature a disk that lifts up off the seat when fluid flows through in the correct direction. When the flow stops or reverses, the disk falls back to the seat, sealing the valve and preventing any reverse flow.

Both designs can be integrated with various pipeline configurations, including horizontal and vertical installations, making them versatile for multiple applications.

Advantages of Cast Steel Check Valves

1. Durability The primary advantage of cast steel is its remarkable strength. This material can withstand significant pressure and temperature fluctuations, making it ideal for demanding environments.

cast steel check valve

3. Low Maintenance Due to their simple mechanical function and robust design, these valves require minimal maintenance over time, reducing operational costs and downtime.

4. Efficiency With proper sizing and installation, cast steel check valves can maintain high levels of efficiency in fluid systems by minimizing turbulence and pressure drops.

5. Wide Range of Applications These valves are suitable for various media, including water, oil, gas, and steam, allowing them to be utilized across industries such as oil and gas, water management, chemical manufacturing, and power generation.

Applications

Cast steel check valves are widely used in numerous applications, reflecting their reliability and effectiveness. Here are a few key areas of use

- Oil and Gas Industry They are critical for pipeline systems, where they protect pumps and compressors from backflow, ensuring operational integrity.

- Water and Wastewater Management In water treatment plants and sewage systems, these valves prevent backflow, helping to maintain consistent flow rates and protect equipment.

- Chemical Processing Chemical plants utilize cast steel check valves to handle various caustic and corrosive materials, ensuring safe and efficient processing.

- Power Generation In power stations, whether hydroelectric or thermal, these valves play a crucial role in maintaining flow direction and preventing any detrimental backflow.

Conclusion

Cast steel check valves are an indispensable tool in fluid management systems. Their robust construction, minimal maintenance requirements, and wide range of applications underscore their importance in ensuring flow efficiency and system reliability. Industries around the globe benefit from their use, relying on these valves to maintain safe operations and protect equipment from harmful backflow. As technology advances, the design and performance of cast steel check valves will continue to evolve, meeting the changing needs of various sectors. Understanding their operation and benefits helps in making informed decisions when selecting the appropriate valve for specific applications.

Share