Sep . 06, 2024 20:55 Back to list

Resilient Seated Gate Valve - Reliable Water Flow Solutions

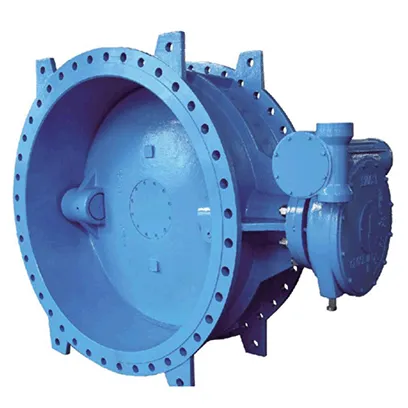

Understanding Resilient Seated Gate Valves A Key Component in Modern Piping Systems

Resilient seated gate valves are integral components in various industrial applications, widely employed in water supply, wastewater management, and fire protection systems. Their unique design and functionality make them increasingly popular in modern piping networks due to their efficiency and reliability.

Design and Construction

The primary feature of a resilient seated gate valve is its gate, which is designed with a soft, resilient material that forms a seal against the valve body when it is closed. Typically, this material is rubber or another elastomer that can withstand various environmental conditions. The valve body itself is made of durable materials such as ductile iron, bronze, or stainless steel, allowing it to endure high pressures and corrosive substances.

The construction of these valves follows a simple yet effective mechanism the gate moves vertically within the valve body. When the valve is open, the gate is fully raised, allowing fluid to flow freely with minimal pressure loss. When closed, the resilient seat compresses against the body, creating a tight seal that prevents any leakage. This feature is vital in ensuring that water systems operate efficiently while minimizing waste.

Advantages of Resilient Seated Gate Valves

One of the primary benefits of resilient seated gate valves is their excellent sealing capability. The elastomeric material used in the seating ensures that they can achieve a tight seal, significantly reducing the risk of leaks. This attribute not only preserves the integrity of the system but also helps in maintaining the pressure levels required for optimal performance.

resilient seated gate valve

Another advantage is their ease of operation. Resilient seated gate valves typically feature a straightforward handwheel or gear mechanism, allowing for quick opening and closing. This simplicity translates into easier installation and maintenance, making them a preferred choice for many engineers and contractors.

Additionally, these valves are resistant to corrosion and wear, thanks to the materials used in their construction. This durability extends their lifespan, often leading to lower replacement and maintenance costs over time. In regions with harsh environmental conditions or where corrosive fluids are present, resilient seated gate valves stand out as a practical and reliable option.

Applications

Resilient seated gate valves find applications across numerous industries. In municipal water supply systems, they are used to control the flow of water and are instrumental during maintenance procedures. They are also widely used in wastewater treatment plants, where managing the flow of effluent is crucial for the environmental impact of the treatment process.

In fire protection systems, resilient seated gate valves are vital for controlling water supply and ensuring that fire hydrants operate effectively when needed. Their ability to provide a dependable seal under pressure makes them a critical component in emergency situations.

Conclusion

In conclusion, resilient seated gate valves are essential elements in modern piping systems, combining reliability with efficient performance. Their innovative design, which incorporates resilient seating materials, ensures a tight seal while offering ease of use and durability. As industries continue to prioritize efficient and sustainable operations, the significance of these valves only stands to grow, cementing their place as a cornerstone in fluid control technology.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025