Feb . 07, 2025 02:45 Back to list

dual plate check valve wafer type

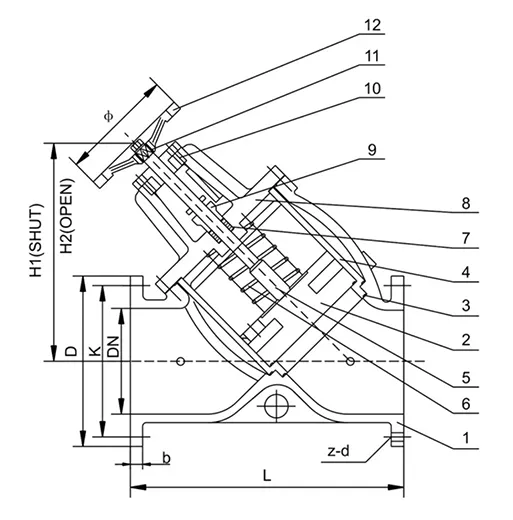

Selecting the right valve for your industrial piping system can significantly impact efficiency and safety, and the dual plate check valve wafer type is a popular choice for professionals seeking reliability and performance. Known for its compact design and effectiveness, these valves provide unparalleled solutions in crucial industrial applications ranging from water treatment facilities to petrochemical refineries.

Professionals in various fields have turned to these valves when searching for solutions that balance cost-effectiveness with superior operational capabilities. The dual plate check valve wafer type's reputation for reducing water hammer, a phenomenon that can cause significant damage to pipelines and equipment, adds to its credibility among experts. The valve mitigates this effect by closing more rapidly than traditional valve designs, preventing the backflow of fluid and maintaining the integrity of the system. Trustworthiness is exemplified through the extensive testing and quality control measures that each valve undergoes before reaching the market. Adhering to strict industry standards and certifications ensures that each valve can be trusted to perform flawlessly in service. For businesses, this translates to fewer unexpected downtimes, thereby enhancing operational reliability and reducing unforeseen expenditure. Advancements in manufacturing technology have further enhanced the performance of dual plate check valves. Modern production techniques allow for more precise engineering, ensuring each valve is optimized for its intended application. High-end models even offer features such as corrosion-resistant coatings, which extend the valve's lifespan in aggressive environments. In summation, the dual plate check valve wafer type remains an industry standard due to its expert design, reliability, and cost-efficiency. For stakeholders in industrial sectors, choosing these valves signifies not just an investment in current needs but a commitment to long-term operational excellence. When selecting your next valve, consider not just the immediate price but the value and reliability that the dual plate check valve offers over the long haul — a wise choice for any discerning professional.

Professionals in various fields have turned to these valves when searching for solutions that balance cost-effectiveness with superior operational capabilities. The dual plate check valve wafer type's reputation for reducing water hammer, a phenomenon that can cause significant damage to pipelines and equipment, adds to its credibility among experts. The valve mitigates this effect by closing more rapidly than traditional valve designs, preventing the backflow of fluid and maintaining the integrity of the system. Trustworthiness is exemplified through the extensive testing and quality control measures that each valve undergoes before reaching the market. Adhering to strict industry standards and certifications ensures that each valve can be trusted to perform flawlessly in service. For businesses, this translates to fewer unexpected downtimes, thereby enhancing operational reliability and reducing unforeseen expenditure. Advancements in manufacturing technology have further enhanced the performance of dual plate check valves. Modern production techniques allow for more precise engineering, ensuring each valve is optimized for its intended application. High-end models even offer features such as corrosion-resistant coatings, which extend the valve's lifespan in aggressive environments. In summation, the dual plate check valve wafer type remains an industry standard due to its expert design, reliability, and cost-efficiency. For stakeholders in industrial sectors, choosing these valves signifies not just an investment in current needs but a commitment to long-term operational excellence. When selecting your next valve, consider not just the immediate price but the value and reliability that the dual plate check valve offers over the long haul — a wise choice for any discerning professional.

Share

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025