nov . 15, 2024 06:31 Back to list

quiet check valve

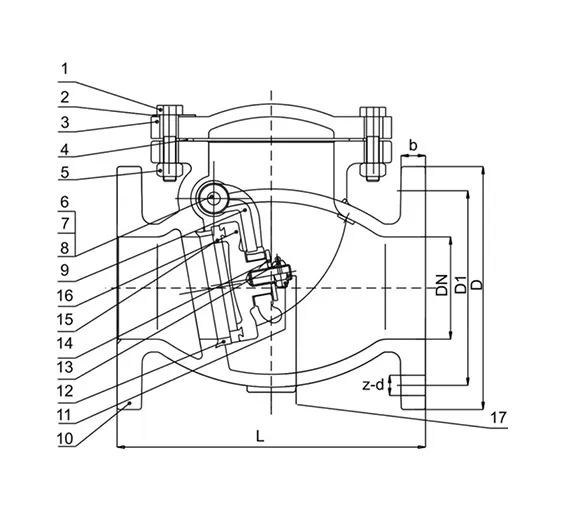

Understanding Quiet Check Valves A Vital Component for Modern Fluid Systems

In various industrial and commercial applications, the effective management of fluid flow is critical. One often overlooked component that plays a significant role in maintaining system integrity and efficiency is the quiet check valve. This specialized device is designed to prevent backflow in pipelines while minimizing noise—a feature that proves particularly advantageous in noise-sensitive environments.

What is a Quiet Check Valve?

A quiet check valve is a type of one-way valve that allows fluid to flow in a single direction while blocking reverse flow. Traditional check valves can often create significant noise when fluid rushes through them, particularly in high-velocity systems. However, quiet check valves utilize advanced engineering techniques and designs to reduce turbulence and dampen the sounds typically associated with fluid movement and valve operation.

The operations of quiet check valves hinge on specific mechanisms. Most commonly, these valves are equipped with spring-loaded disc or flap mechanisms that provide a smooth, gradual closure. By reducing the abrupt stop of flowing liquid, the quiet check valve efficiently mitigates the shock waves that lead to noise. This makes them ideal for applications in hospitals, laboratories, and residential areas where maintaining a quiet environment is essential.

Applications and Benefits

quiet check valve

Quiet check valves can be found across various industries, including water treatment, HVAC systems, food and beverage processing, and pharmaceutical manufacturing. In the water treatment sector, for example, these valves help regulate flow within piping systems without introducing disruptive sounds, ensuring that operations can run smoothly without disturbing nearby operations or residential areas.

The benefits of incorporating quiet check valves into a fluid management system extend beyond just noise reduction. By preventing backflow, these valves help maintain the consistency and quality of the process fluid, which is particularly important in sensitive applications. Furthermore, their ability to minimize pressure fluctuations in the system can lead to reduced wear and tear on pumps and pipes, enhancing the longevity of equipment.

Installation and Maintenance

Installing a quiet check valve requires careful consideration of the system design. Proper orientation, appropriate sizing, and location within the pipeline are crucial for optimal performance. Maintenance is also manageable, as these valves typically have durable materials designed to withstand wear. Regular inspections can ensure that the valves function effectively and help identify any signs of wear or failure before they lead to significant issues.

Conclusion

In summary, quiet check valves represent a critical innovation in fluid dynamics, combining functionality with noise reduction. As industries continue to emphasize efficiency and comfort, these valves serve as an essential component for improving system performance. Ensuring the seamless flow of fluids while preserving a quiet environment will remain a priority for engineers and facilities managers alike, highlighting the enduring importance of quiet check valves in modern applications.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025