nov . 09, 2024 18:48 Back to list

Understanding the Functionality of Double Ball Check Valves in Fluid Systems

The Double Ball Check Valve A Vital Component in Fluid Control Systems

In the realm of fluid mechanics and control systems, efficient and reliable flow control devices are paramount for a variety of industrial applications. Among these devices, the double ball check valve holds a significant place. Its design and functionality not only ensure the proper regulation of fluid flow but also enhance system safety and efficiency. This article aims to elucidate the double ball check valve's design, working principles, applications, and advantages over other types of valves.

Design and Working Principle

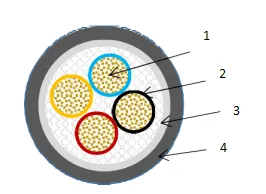

The double ball check valve, as the name suggests, consists of two spherical balls that serve as the main sealing elements. The valve is typically cylindrical in shape and features two seats, one for each ball. When fluid flows through the valve, the pressure causes one of the balls to be pushed against its respective seat, creating a seal that prevents backflow. If the pressure on the opposite side of the valve exceeds the pressure on the inlet side, the other ball is pushed away from its seat, allowing flow in the reverse direction but preventing backflow at any unintended time.

One of the defining features of the double ball check valve is its ability to provide redundancy. Should one ball fail to seal properly due to wear, debris, or other factors, the second ball acts as a backup, ensuring that the flow control system remains operational. This makes the double ball check valve ideal for critical applications where backflow could lead to system failure or safety hazards.

Applications

The double ball check valve is utilized across various industries, including

1. Water and Wastewater Management In municipal water supply and sewage systems, these valves are essential in maintaining pressure and preventing contamination from backflow, which is crucial in ensuring public health.

3. Chemical Processing The ability to handle corrosive materials makes double ball check valves suitable for chemical plants, where they prevent the unintended reversal of flow that could lead to cross-contamination or hazardous situations.

4. HVAC Systems In heating, ventilation, and air conditioning systems, these valves help maintain the desired flow direction, preventing inefficiencies and ensuring optimal performance of the system.

double ball check valve

5. Food and Beverage Industry Being easy to clean and maintain, these valves are often used in sanitary applications, preventing backflow and ensuring the quality and safety of consumable products.

Advantages

The double ball check valve offers several benefits that make it a preferred choice in many applications

- Redundancy As previously mentioned, the dual-ball design provides a backup sealing mechanism, increasing reliability compared to single ball check valves.

- Low Maintenance These valves generally require less frequent maintenance due to their robust design, which translates to lower operating costs over time.

- Ease of Installation The compact and simple design allows for straightforward installation, reducing downtime during system setup or upgrades.

- Versatility Capable of handling a wide range of fluids, including liquids and gases, the double ball check valve can be adapted for various industrial needs.

- Temperature and Pressure Resistance Depending on the materials used in its construction, these valves can withstand extreme temperatures and pressures, making them suitable for demanding environments.

Conclusion

In summary, the double ball check valve is an essential component in fluid control systems, offering numerous advantages that enhance reliability and safety across various industrial sectors. Its innovative design and functionality make it a superior choice for applications where backflow prevention is critical. As industries continue to evolve and demand more from their fluid control systems, the double ball check valve will undoubtedly maintain its pivotal role in ensuring operational efficiency and safety. As we move toward a more sustainable future, investing in efficient technologies like the double ball check valve will be crucial in managing resources effectively and responsibly.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025